Blog

Top Benefits of Heavy Duty Racking System for Industrial Storage Solutions?

In the world of industrial storage, a heavy duty racking system stands out. It offers strength and durability, crucial for various workplaces. These systems can support significant weights, making them perfect for warehouses and manufacturing settings.

Many businesses face challenges with space and organization. A heavy duty racking system can efficiently address these issues. It allows companies to maximize vertical space while maintaining accessibility. This system is not just about storage; it's about improving workflow.

However, choosing the right heavy duty racking system isn't always simple. Different industries have unique needs. A one-size-fits-all approach may lead to inefficiencies or safety concerns. Careful consideration and assessment of specific requirements are essential for optimal results.

Importance of Heavy Duty Racking in Industrial Environments

In industrial environments, heavy duty racking systems are crucial for effective storage. These systems maximize vertical space, allowing for higher storage capacity. This is particularly important in warehouses where every square foot is valuable. Every inch counts when dealing with limited floor space.

Additionally, heavy duty racks enhance organization. They keep items accessible and categorized. This reduces time spent searching for products. Workers can find what they need faster, which increases overall efficiency. However, it's essential to ensure proper weight limits are followed. Overloading can lead to safety hazards.

Another key aspect is flexibility. Heavy duty racking can be reconfigured as needs change. This adaptability is vital for companies that often update inventory. Still, frequent changes may disrupt order until adjustments are made. It's a balance between maintaining organization and making necessary expansions. Ultimately, effective use of heavy duty racking can lead to improved performance in industrial settings.

Types of Heavy Duty Racking Systems Available for Storage

Heavy-duty racking systems are essential for maintaining organized industrial storage. They come in various types to suit different needs. Selective racks are the most common. These allow easy access to each pallet. They fit well in warehouses with high inventory turnover. But, they require more floor space.

Drive-in racks optimize space effectively. They use a first-in, last-out approach. This is beneficial for bulk storage. However, accessibility can be an issue if not managed properly. Consider using push-back racking for greater efficiency. This system lets you store multiple pallets deep and saves space. Still, it can complicate inventory management.

Cantilever racking is great for long or heavy items. It offers adjustable arms to accommodate varying lengths. This versatility can be a game changer. However, improper loading might lead to safety hazards. Remember the importance of regular inspections. Heavy-duty racking systems, when utilized correctly, may vastly improve storage capacity. Reflecting on your choice is vital for long-term success.

Top Benefits of Heavy Duty Racking System for Industrial Storage Solutions - Types of Heavy Duty Racking Systems Available for Storage

| Racking System Type | Load Capacity (lbs) | Height (ft) | Shelf Depth (inches) | Material | Best Use Case |

|---|---|---|---|---|---|

| Selective Racking | 3000 | 12 | 48 | Steel | General storage and warehouse |

| Drive-In Racking | 4500 | 10 | 60 | Steel | Bulk storage, high-density |

| Cantilever Racking | 6000 | 15 | 36 | Steel | Storing long items like pipes and lumber |

| Pallet Flow Racking | 5000 | 14 | 48 | Steel | FIFO inventory management |

| Multi-Tier Racking | 2500 | 20 | 30 | Steel | Maximize vertical space in small warehouses |

Key Advantages of Heavy Duty Racking for Space Utilization

A heavy-duty racking system revolutionizes industrial storage. It maximizes the use of available space effectively. Businesses often struggle with floor space. Heavy-duty racks allow vertical storage, making warehouses more organized. This vertical solution helps in utilizing every inch of height.

Investing in a robust racking system saves time and effort. Workers can find items easily. It improves workflow efficiency in busy environments. However, it requires thoughtful planning. Poorly designed layouts can lead to confusion. Too much height might make top shelves hard to reach. Balance is key to effective storage.

These racks are often very durable. They withstand heavy loads and rough handling. Quality construction means fewer replacements. But, users should regularly inspect their condition. Staying proactive can prevent costly accidents. Proper maintenance ensures longevity and performance. A well-organized warehouse leads to smoother operations and better productivity.

Safety Considerations with Heavy Duty Racking Systems

Heavy-duty racking systems offer numerous benefits for industrial storage, with safety being a top priority. Proper installation and maintenance are crucial. Unstable racking can lead to accidents. Regular inspections are essential to ensure that everything is in place and secure.

To enhance safety, consider these tips. Always load racks evenly. This prevents tipping and collapses. Train staff on proper storage techniques. Employees should know the weight limits. Education reduces risks significantly. Use safety barriers or netting. These additions can prevent items from falling.

Lighting in storage areas matters too. Adequate visibility helps workers avoid hazards. Poor lighting can lead to mistakes. Keep aisles clear to facilitate movement. Clutter can obstruct emergency exits. An organized space enhances safety and efficiency. Ensure that fire extinguishers are easily accessible. Regular fire safety drills help maintain preparedness.

Top Benefits of Heavy Duty Racking System for Industrial Storage Solutions

This chart illustrates the top five benefits of heavy-duty racking systems for industrial storage solutions. The data reflects the percentage impact of each benefit on overall storage effectiveness, emphasizing the importance of safety considerations and efficiency in industrial environments.

Cost-Effectiveness of Heavy Duty Racking for Industrial Warehouses

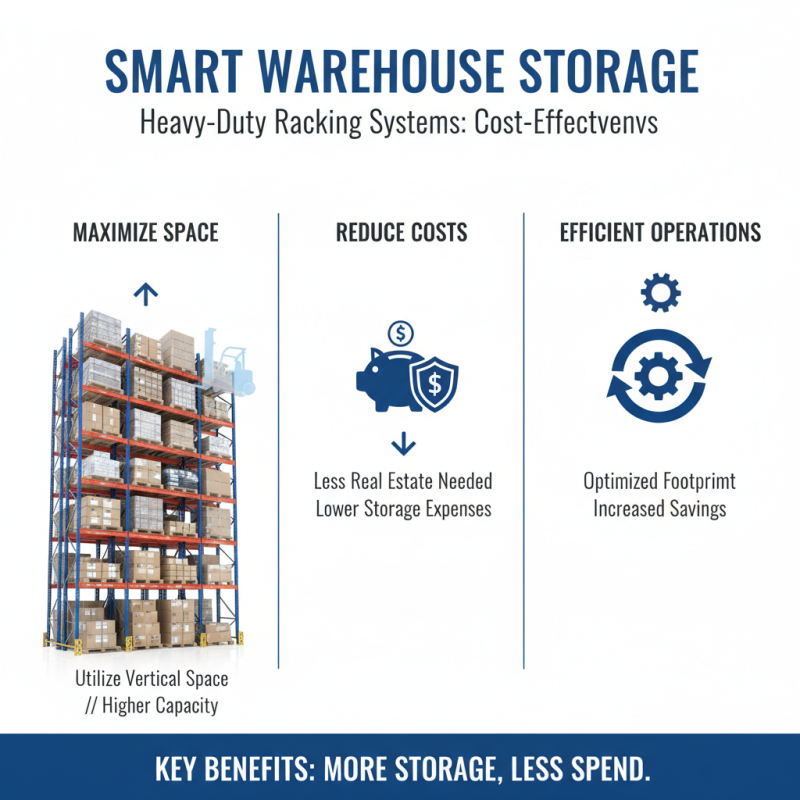

When it comes to industrial warehouses, cost-effectiveness is a critical factor. Heavy duty racking systems can drastically reduce storage costs. They maximize vertical space, allowing for higher storage capacity without needing more square footage. This is especially beneficial in tight warehouse environments. By utilizing every inch, businesses can save money on real estate.

Additionally, heavy duty racking enhances operational efficiency. It allows for easy access to stored items. Workers can retrieve products quickly, reducing time spent searching for items. This efficiency often leads to increased productivity. A well-organized warehouse fosters a better workflow.

Tip: Regularly assess your racking system. Make adjustments as needed to improve function. Remember, even heavy duty racks need maintenance.

Another crucial aspect is the initial investment. While heavy duty racking may seem costly upfront, it pays off in the long term. Reduced damages and improved safety lead to further savings. However, ensure your racking configuration matches your operational needs. Over-optimizing can lead to issues later.

Tip: Train team members on safe and effective rack use. Understanding the system can prevent accidents and maximize lifespan. Keeping up with training is an ongoing process.

Related Posts

-

Why Heavy Duty Racking is Essential for Efficient Warehouse Storage Solutions

-

How to Choose the Right Commercial Racking System for Your Business Needs

-

Ultimate Guide to Choosing the Best Pallet Shelving for Your Warehouse in 2025

-

Top Heavy Duty Racking Systems for Efficient Warehouse Storage in 2025

-

2026 Best Racking System Solutions for Efficient Storage Management?

-

Top 10 Racking Shelves for Efficient Storage Solutions?