Blog

What is Cantilever Racking and How Does It Benefit Your Warehouse Storage

In the ever-evolving landscape of warehouse management, efficient storage solutions play a pivotal role in optimizing space and enhancing productivity. One such innovative solution is cantilever racking, a system designed to support long and bulky items while maximizing floor space. According to industry expert John Anderson, a prominent voice in warehouse logistics, "Cantilever racking is not just a storage solution; it transforms how businesses handle their inventory by providing unparalleled access and flexibility."

This unique racking system allows for easy loading and unloading, making it an ideal choice for warehouses dealing with materials such as lumber, pipes, and steel. By embracing cantilever racking, businesses can reduce clutter and improve accessibility, leading to increased efficiency in operations. The benefits extend beyond mere space management, as cantilever racking also facilitates better workflow and inventory tracking, ultimately driving profitability.

As the demand for effective warehouse solutions grows, understanding the advantages of cantilever racking becomes essential for businesses looking to stay competitive in a crowded market. This article will delve into the intricacies of cantilever racking, exploring its benefits and how it can be a game-changer for your warehouse storage strategies.

What is Cantilever Racking?

Cantilever racking is a specialized storage solution designed to handle long and bulky items that traditional racking systems may struggle with. This type of racking consists of horizontal arms extending from a vertical structure, allowing for easy access and efficient organization of goods. It is particularly beneficial for industries that deal with timber, metal, plumbing materials, and other lengthy products. According to a report from the Material Handling Industry of America, implementing cantilever racking can increase storage efficiency by up to 70%, making it an ideal choice for warehouses looking to maximize their space.

The design of cantilever racking promotes versatility and flexibility in storage arrangements. The open structure allows for the accommodation of items of various lengths without the need for cumbersome shelving units that can limit adjustments. Studies indicate that warehouses utilizing cantilever systems can reduce product retrieval times by approximately 30%, which significantly enhances overall operational efficiency. Additionally, these racking systems can be customized in height and depth, catering to specific warehouse needs while ensuring safety and stability under heavy loads. Thus, cantilever racking serves as a vital component in the optimization of warehouse storage practices.

Benefits of Cantilever Racking in Warehouse Storage

Key Features of Cantilever Racking Systems

Cantilever racking systems are designed specifically for the storage of long, bulky, or irregularly shaped items that traditional shelving cannot accommodate. One of the key features of these systems is their adjustable arm design, which allows users to modify the spacing between the arms as needed. This flexibility makes it easy to store a variety of products, from lumber and pipes to furniture and large equipment, maximizing vertical space without compromising accessibility.

Another significant advantage of cantilever racking is its open design, which eliminates the need for front columns. This feature not only enhances visibility and ease of access but also allows for the efficient management of inventory. The absence of obstructions means that forklifts and other equipment can maneuver freely, reducing the risk of damage to stored goods. Additionally, cantilever racks are typically constructed from robust materials, ensuring durability and longevity, even under the strain of heavy loads.

What is Cantilever Racking and How Does It Benefit Your Warehouse Storage - Key Features of Cantilever Racking Systems

| Feature | Description | Benefits |

|---|---|---|

| Adjustable Arms | Arms can be easily adjusted to accommodate different product sizes. | Increases versatility for varying inventory types. |

| Open Design | Allows for easy access to products from all sides. | Enhances retrieval efficiency and reduces time spent picking orders. |

| Heavy-Duty Construction | Built to support heavy and bulky items. | Improves safety and reduces risk of damage to both goods and racking. |

| Space Efficiency | Maximizes vertical storage space while maintaining an organized layout. | Increases storage capacity without expanding the warehouse footprint. |

| Customization Options | Can be tailored to fit specific storage needs and warehouse layouts. | Provides a tailored solution that meets unique operational requirements. |

Benefits of Cantilever Racking for Warehouse Storage

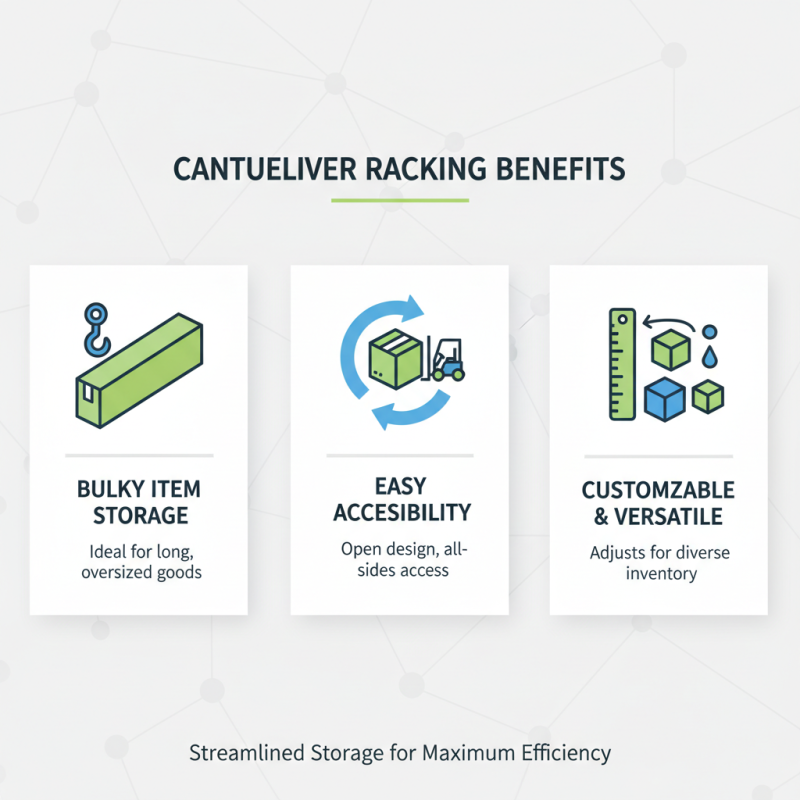

Cantilever racking is a highly efficient storage solution designed specifically for large, bulky items that traditional shelving cannot accommodate. One of the most significant benefits of cantilever racking is its flexibility. The open design allows for easy access to products from all sides, which streamlines warehouse operations and reduces the need for complex maneuvers during loading and unloading. This type of racking can be customized in height and length to suit various inventory types, making it ideal for warehouses that handle different types of goods, from timber and steel to large appliances.

Another advantage of cantilever racking is its enhanced space utilization. With the ability to store items vertically and the absence of front upright columns, warehouses can maximize floor space, resulting in higher storage density. This optimization leads to improved inventory management, as products are organized efficiently, making them easier to find and retrieve. Additionally, the robust construction of cantilever racks supports significant weights, providing a safe and reliable way to store heavy loads, further enhancing warehouse efficiency and productivity.

How to Choose the Right Cantilever Racking for Your Needs

When choosing the right cantilever racking for your warehouse needs, it's essential to assess the specific types of items you'll be storing. Cantilever racking is particularly advantageous for long, bulky items such as pipes, lumber, or furniture. Consider the length, weight, and dimensions of your inventory to ensure that the chosen racking system can accommodate these factors. Additionally, identifying the maximum load capacity of the racking is vital to prevent overloading and ensure safety.

Another key factor is the configuration of your storage space. Evaluate the layout of your warehouse to determine how much vertical and horizontal space is available for installation. Cantilever racks come in various heights and arm lengths, allowing you to maximize storage efficiency. Additionally, consider whether you need single-sided or double-sided racks based on the accessibility of your warehouse. Lastly, it's important to factor in future growth and changes in inventory; selecting a flexible and modular racking system can facilitate easy expansion as your storage needs evolve.

Maintenance and Safety Considerations for Cantilever Racking Systems

When utilizing cantilever racking systems in a warehouse, maintenance and safety are crucial for ensuring optimal performance and minimizing risks. Regular inspections should be conducted to check for any signs of wear, damage, or misalignment in the racking structure. This includes looking for bent arms, cracked bases, or loose bolts, which can compromise the integrity of the system and pose safety hazards for workers.

**Tips:** Implement a routine maintenance schedule where each component of the cantilever rack is assessed at least once a month. Keep a log of inspections and repairs to track the system's condition over time. This proactive approach not only enhances safety but also prolongs the lifespan of the racking system.

In addition to maintenance, safety training for warehouse staff is essential. Employees should be educated on the correct loading techniques, including distributing weight evenly and adhering to the load limits specified for each arm. Proper training will reduce the likelihood of accidents and ensure that the cantilever racking is used effectively without overloading.

**Tips:** Organize regular safety training sessions and refreshers for all warehouse personnel. Utilize visual aids or signage to highlight safe loading practices and emergency procedures related to cantilever racking systems. This ensures that everyone is well-informed and reinforces a culture of safety within the warehouse environment.

Related Posts

-

Why Heavy Duty Racking is Essential for Efficient Warehouse Storage Solutions

-

How to Choose the Right Warehouse Pallet Racks for Your Business Needs

-

10 Best Racking and Shelving Solutions for Efficient Storage Management

-

Top 10 Warehouse Racking Systems to Maximize Space and Efficiency

-

How to Choose the Best Industrial Storage Solutions for Your Business Needs

-

Why You Should Choose Heavy Duty Storage Racks for Your Garage or Warehouse