Blog

What is Cantilever Racking and How Does it Work?

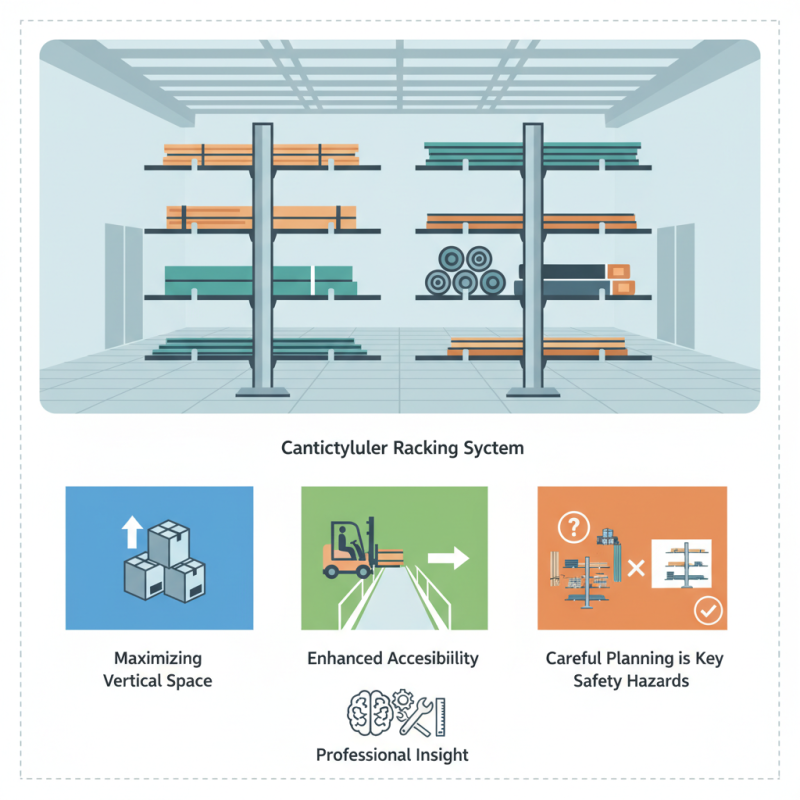

Cantilever racking plays a crucial role in modern storage solutions. According to industry expert John Smith, "Cantilever racking maximizes vertical space and enhances accessibility." This system is designed for storing long or bulky items effectively. It features horizontal arms extending from vertical columns. This design allows for easy loading and unloading.

In warehouses, cantilever racking addresses the challenge of organizing long materials. It creates more open floor space. However, it is essential to evaluate the layout carefully. Poor planning can lead to wasted space and inefficiencies. Identifying the right dimensions is key. Misjudging can result in safety hazards too.

The implementation of cantilever racking often requires professional insight. Understanding its operation helps businesses optimize storage. Clear paths are necessary for maneuvering equipment. Accessibility is essential for daily operations. Failing to consider these factors may present challenges. A thoughtful approach can yield better organization and flow in storage environments.

What is Cantilever Racking? An Overview of Its Definition and Purpose

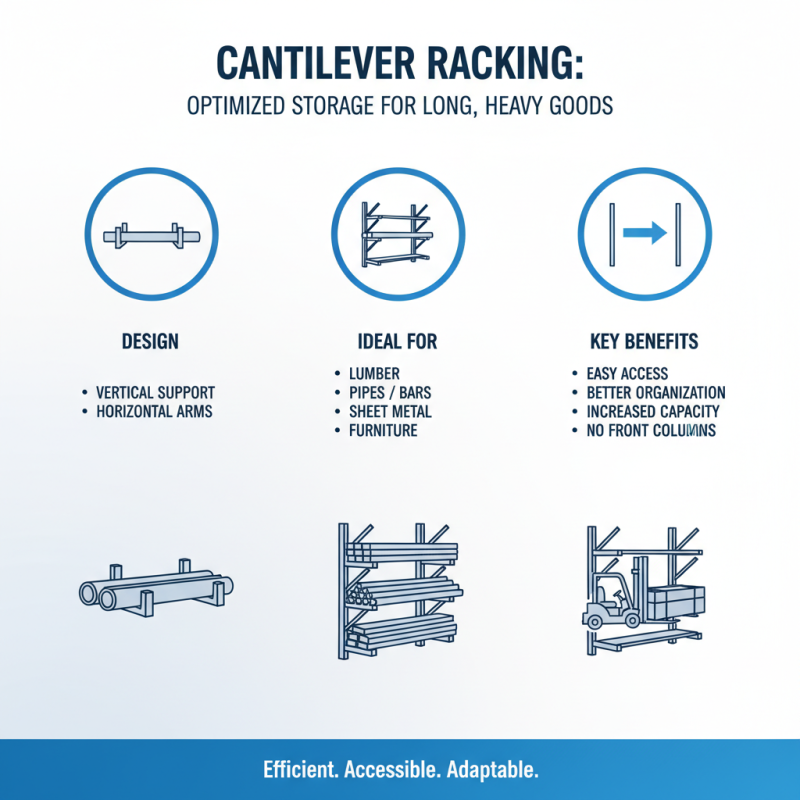

Cantilever racking is a storage solution designed for bulky items. It provides an efficient way to store long, heavy products like lumber and pipes. This type of racking features a series of horizontal arms that extend from a vertical support. They allow for easy access and organization of materials.

When using cantilever racks, it's important to consider visibility. Items should be easily seen and accessible. Ensure that heavier items are stored at lower levels to prevent accidents. Having an organized system can save time and reduce frustration.

Tip: Regularly check the stability of the racks. Over time, wear and tear can weaken the structure. Proper maintenance ensures safety and longevity.

In addition, consider the layout of your workspace. Efficiently arranging items on cantilever racks can improve workflow. For example, keep frequently used items at the front. This minimizes the time spent searching for materials. Although designing an ideal system may take time, the benefits are worth it.

Key Components of Cantilever Racking: Arms, Bases, and Columns Explained

Cantilever racking is a specialized storage solution. It effectively stores long, bulky items like lumber and pipes. This system consists of essential components: arms, bases, and columns. Each plays a crucial role in the overall functionality.

The arms are the most visible parts. They extend horizontally from the columns. This design allows easy access to stored items. Arms can be adjusted to fit different lengths. Some users find this flexibility beneficial. However, too much adjustment can lead to instability. So, careful consideration is needed.

The bases provide stability. They anchor the entire structure and must be robust. A solid base reduces the risk of accidents. Columns, on the other hand, support the weight of the load. They must be tall and strong. Yet, if not installed correctly, they can cause issues. Overall, understanding these components is vital for effective use. Proper installation and maintenance are key to maximizing their potential.

What is Cantilever Racking and How Does it Work?

| Component | Description | Dimensions (inches) | Load Capacity (lbs) |

|---|---|---|---|

| Arms | Holds the load, extending from the upright. | 36 | 1500 |

| Bases | Provides stability and supports vertical columns. | 48 | N/A |

| Columns | Vertical supports that hold the arms. | 96 | 3000 |

Benefits of Using Cantilever Racking in Warehousing and Storage Solutions

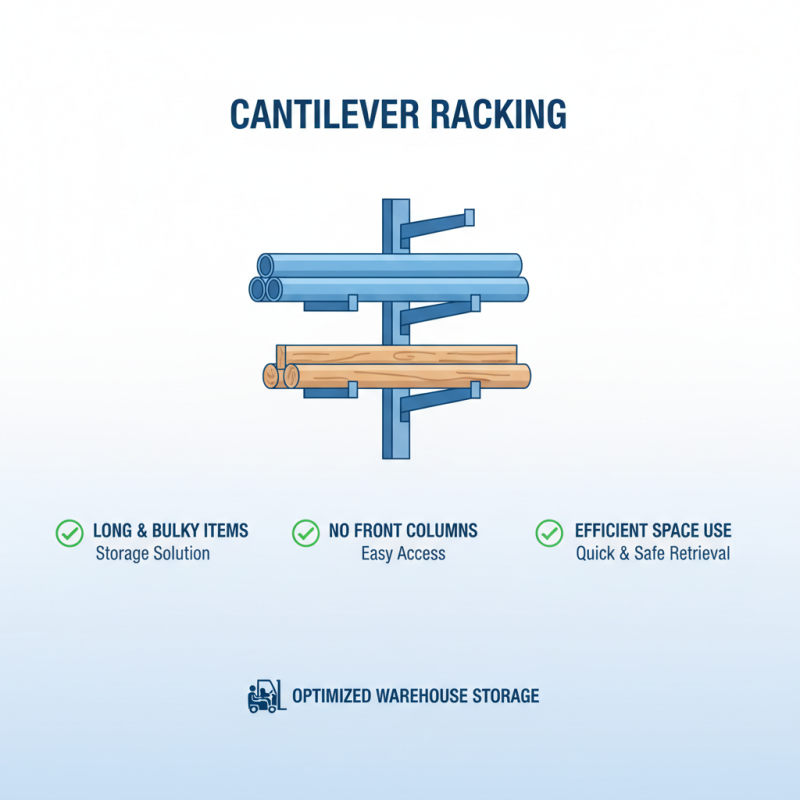

Cantilever racking is a storage solution designed for long and bulky items. It provides flexibility and easy access. This type of racking eliminates the need for front columns. As a result, warehouse space is used more efficiently. Employees can retrieve items quickly and safely.

One major benefit of cantilever racking is adjustable shelving. This allows businesses to customize the storage height. They can accommodate various sizes of products. Additionally, it helps in optimizing inventory management. Better organization leads to faster order fulfillment. Workers spend less time searching for items. However, some may overlook the importance of proper weight distribution.

Another advantage is increased storage capacity. Cantilever racks can hold heavier loads. This is particularly useful for warehouses dealing with timber or furniture. These structures can also be extended to fit specific needs. Yet, if not installed correctly, safety risks arise. Regular inspections are needed to ensure stability. Balancing efficiency and safety is a critical aspect of using cantilever racking.

Industry Applications of Cantilever Racking: Sectors That Benefit Most

Cantilever racking is essential in many industries. It allows for efficient storage of long and bulky items. Sectors like manufacturing often rely on this system for steel pipes or lumber. Their design aids in maximizing vertical space. This feature is crucial in warehouses where floor space is limited.

The construction industry greatly benefits as well. They often have irregularly shaped materials that need secure storage. Cantilever racks provide flexibility. However, it requires careful planning to ensure safety. Misjudging weight limits can lead to accidents. Additionally, improper loading can hinder accessibility, creating workflow delays.

Additionally, the furniture sector finds value in cantilever racking. With varying sizes of products, these racks can adapt. However, choosing the right configuration can be challenging. One must consider the weight distribution on each arm. This consideration is often overlooked, leading to instability. In practice, it is a balancing act of efficiency and safety.

Best Practices for Installing and Maintaining Cantilever Racking Systems

When installing cantilever racking systems, attention to detail is crucial. These systems are ideal for storing long items like lumber or pipes. They utilize vertical columns and arms, creating open space for large loads. According to industry reports, improper installation can reduce load capacity by up to 30%. This fact emphasizes the need for precise alignment and level foundation support.

Regular maintenance is equally important. Inspections should occur monthly. Check for signs of wear, rust, or damage. A recent survey states that 40% of warehouses overlook regular upkeep, risking safety. Issues often escalate unnoticed, leading to costly repairs or accidents. Operators must encourage a culture of diligence and awareness among staff.

Training plays a key role in effective usage. Employees should understand load limits and proper stacking techniques. Even with proper systems in place, without knowledgeable staff, risks remain. A possible oversight might be underestimating the importance of communication regarding weight distribution. Fostering a proactive mindset around these aspects can keep operations safe and efficient.

Related Posts

-

2025 Top Cantilever Racking Solutions for Efficient Warehouse Storage

-

Top 5 Best Cantilever Racking Systems for Maximizing Storage Efficiency

-

Top 5 Benefits of Using Warehouse Shelving Racks for Efficient Storage Solutions

-

How to Build Your Own Pallet Shelving for Maximum Storage and Style?

-

2026 Top Trends in Pallet Racking Innovations and Solutions?

-

Top 5 Benefits of Using Warehouse Pallet Racks for Maximum Storage Efficiency