Blog

How to Choose the Right Warehouse Pallet Racks for Your Business Needs

Choosing the right warehouse pallet racks is crucial for optimizing storage efficiency and streamlining operations in any business. According to the Material Handling Institute, the warehouse pallet racks market is projected to reach $12.5 billion by 2025, reflecting the growing demand for effective storage solutions in an increasingly complex supply chain landscape. Properly selected pallet racks contribute not only to space optimization but also to improved safety and accessibility of inventory, which are fundamental to enhancing overall productivity.

Industry expert Dr. Emily Chang, a leading authority on warehouse optimization, emphasizes the importance of making informed choices when selecting pallet racks. She states, "Understanding the specific needs of your warehouse and aligning them with the right type of pallet racks is vital for maximizing operational efficiency." This sentiment underscores the need for businesses to thoroughly evaluate their storage requirements, available space, and inventory types before committing to a pallet rack system. By doing so, companies can leverage warehouse pallet racks to create a more organized and efficient workflow, ultimately driving success in their operations.

Understanding Warehouse Pallet Rack Types and Their Applications

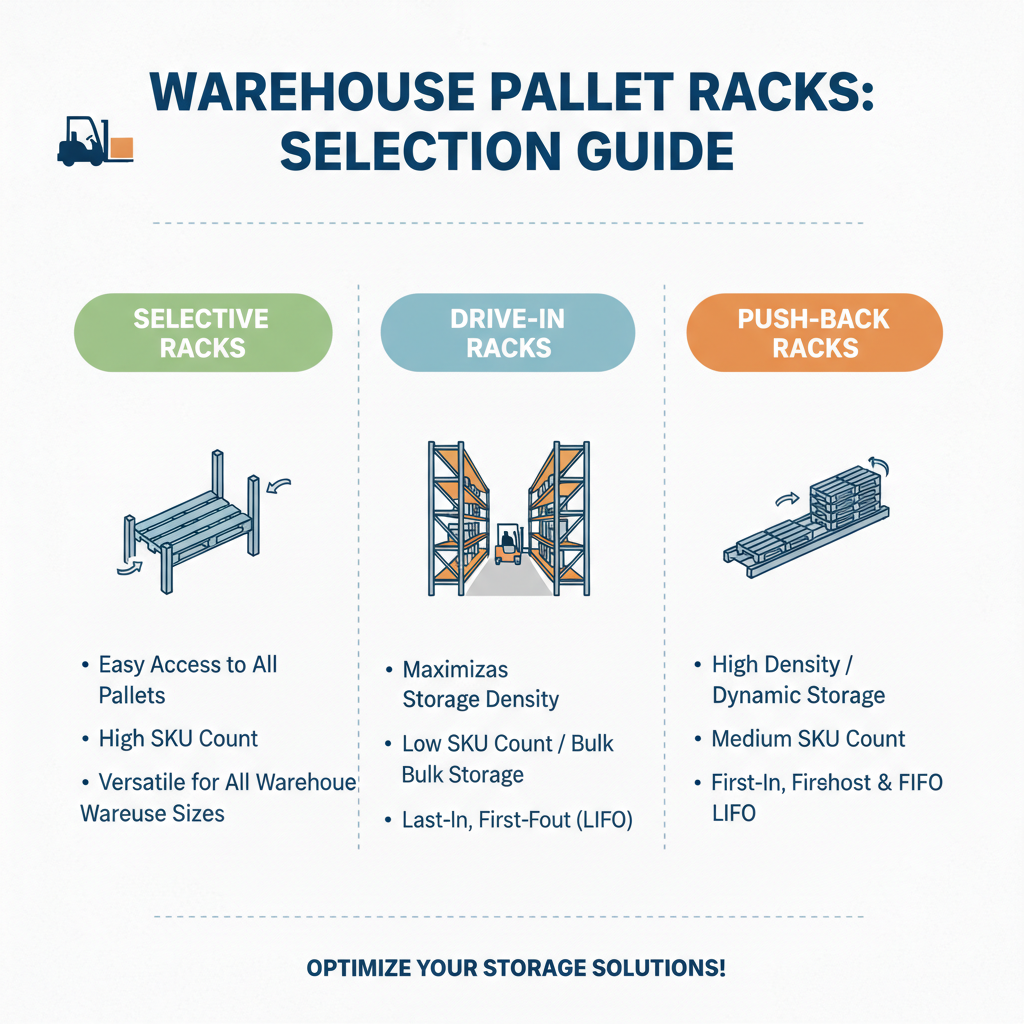

When selecting warehouse pallet racks, it is crucial to understand the various types available and their specific applications to effectively meet your business needs. The most common types include selective racks, drive-in racks, and push-back racks.

Selective racks are versatile and allow easy access to all pallets, making them ideal for businesses with a high SKU count. Their straightforward design ensures efficient inventory management and is suitable for both small and large warehouses.

On the other hand, drive-in racks maximize warehouse space by enabling forklifts to drive directly into the storage area, accommodating high-density storage for similar products. This system is particularly beneficial for businesses with large quantities of a single item. Push-back racks combine the benefits of both selective and drive-in systems, allowing for higher storage density while still providing front access to pallets.

Understanding these types and their unique advantages will help you make informed decisions that align your storage capabilities with your operational requirements.

Evaluating Your Storage Space and Inventory Needs

When selecting the appropriate warehouse pallet racks for your business, evaluating your storage space and inventory needs is crucial. Start by conducting a thorough assessment of your warehouse layout, including both horizontal and vertical dimensions. Consider the height of your ceilings and the width of your aisles to determine how tall and deep your racks can be. This will help you maximize your available space while ensuring easy access to your products.

Next, evaluate your inventory levels and types of products you store. If your business frequently deals with high-volume items, consider using selective racks, which allow easy access to individual pallets. On the other hand, if you manage a diverse range of products with varying sizes, a drive-in or push-back rack may be more suitable, providing efficient storage while minimizing the need for picking multiple items. By aligning your rack selection with your specific storage space and inventory dynamics, you can enhance efficiency, accessibility, and overall productivity in your warehouse operations.

Assessing Weight Capacity and Rack Structural Integrity

When selecting warehouse pallet racks, assessing weight capacity and rack structural integrity is crucial to ensure safety and efficiency in your storage operations. The weight capacity of a rack is determined by the materials used in its construction, the design of the rack, and how it is anchored to the floor. It is essential to accurately calculate the total weight of the products to be stored, accounting for their distribution across the racks to avoid overloading.

Tips: Always consult with a rack expert to verify the manufacturer's specifications regarding weight limits. Regularly inspect your pallet racking systems for signs of damage or wear, as structural integrity can diminish over time, especially in busy warehouses where heavy loads are frequently moved.

In addition, consider the types of materials used in the production of pallet racks. Steel racks, for example, offer excellent structural integrity and higher weight capacities compared to those made from lighter materials. Choosing racks with a sturdy design, such as bolted connections rather than welded ones, can further enhance the strength and longevity of your racking system.

Choosing Between Adjustable and Static Pallet Racks

When selecting the right pallet racks for your warehouse, one of the crucial decisions revolves around choosing between adjustable and static pallet racks. Adjustable pallet racks offer flexibility, allowing businesses to modify shelf heights and configurations according to their varying inventory needs. This adaptability is ideal for companies that frequently change their product lines or seasonal stock levels. Being able to customize the storage system can optimize space utilization and improve overall efficiency.

On the other hand, static pallet racks provide a more permanent solution, designed for specific items that do not change frequently. They usually offer a sturdier structure since they are built for particular dimensions and weights. Businesses with consistent inventory types may find static racks to be more cost-effective in the long run, as they require less maintenance and can maximize their storage capabilities without the need for constant adjustments. Understanding these differences is essential for making an informed choice that aligns with your business operations and storage requirements.

Determining Additional Features for Optimal Warehouse Efficiency

When selecting warehouse pallet racks, determining additional features is essential for maximizing efficiency and productivity. According to a report by the Material Handling Industry of America (MHIA), implementing optimized storage solutions can improve warehouse efficiency by up to 30%. Therefore, it’s critical to consider features such as adjustable shelving, load capacity, and compatibility with various pallet sizes.

Tips: Assess your inventory turnover rates and choose pallet racks that can easily adapt to your changing storage needs. For instance, wire decking can enhance visibility and airflow, reducing inventory losses due to damage or spoilage, which is vital for businesses handling perishable goods.

Moreover, safety features such as pallet rack protectors and seismic bracing should not be overlooked. The Occupational Safety and Health Administration (OSHA) highlights that proper safety measures can reduce workplace accidents by nearly 40%. Investing in quality racks that prioritize safety ensures a secure environment for your workers and your inventory alike.

Tips: Regularly inspect your pallet rack systems for any signs of wear and document any reported issues to maintain compliance with safety standards.

Related Posts

-

How to Choose the Best Industrial Storage Solutions for Your Business Needs

-

Top 10 Industrial Storage Solutions to Optimize Your Warehouse Space

-

Top 5 Benefits of Using Warehouse Pallet Racks for Maximum Storage Efficiency

-

Top 10 Warehouse Racking Systems to Maximize Space and Efficiency

-

10 Best Racking and Shelving Solutions for Efficient Storage Management

-

Top 10 Racking System Solutions for Optimal Warehouse Efficiency