Blog

How to Choose the Right Warehouse Shelving for Your Needs?

Choosing the right warehouse shelving can seem daunting. Jon Stevens, a warehouse operations expert, emphasizes, “The right shelving optimizes space and efficiency.” With the right selections, businesses enhance their storage and streamline operations.

Warehouse shelving comes in various types. Each type serves different purposes and can impact workflow. A well-chosen shelving system reduces clutter, making it easier for staff to find items quickly. It saves time and boosts productivity. However, choosing the wrong shelving can lead to inefficiency.

Consider every detail before deciding. Measure available space carefully. Reflect on the weight capacity and materials needed. Skipping these steps can have costs later. A mistake in shelving choice is often costly and inconvenient. Each decision in warehouse shelving is crucial for a well-functioning environment.

Understanding Your Storage Requirements

Choosing the right warehouse shelving starts with understanding your storage needs. Think about the types of items you store. Are they large or small? Heavy or light? Evaluating these factors helps determine the best shelving type. For instance, heavy-duty shelves suit bulky items, while smaller units work for lighter products.

Consider the space available. Do you have high ceilings or limited floor space? Tall shelves can maximize vertical storage, but they require careful access planning. It's worth contemplating the arrangement of your warehouse. Is there room for equipment to move freely? A clear layout boosts efficiency. Often, companies overlook this factor and regret it later.

Reflect on future growth. Will your storage needs change over time? Flexible shelving options allow for easy adjustments. Investing in adaptable solutions can save costs long-term. Don't rush this decision; take time to assess your requirements thoroughly. It’s a crucial step that impacts productivity and organization.

How to Choose the Right Warehouse Shelving for Your Needs?

| Storage Type | Weight Capacity (per shelf) | Material | Dimensions (W x D x H) | Ideal Use Case |

|---|---|---|---|---|

| Boltless Shelving | 800 lbs | Steel | 48" x 24" x 72" | General Storage |

| Adjustable Shelving | 600 lbs | Wood/Metal | 36" x 18" x 60" | Retail Storage |

| Heavy-Duty Industrial Shelving | 1200 lbs | Steel | 48" x 36" x 96" | Warehouse Equipment |

| Wire Shelving | 200 lbs | Wire/Steel | 48" x 24" x 72" | Food Storage |

| Cantilever Racking | 1500 lbs | Steel | Varies by configuration | Lumber and Pipe Storage |

Evaluating Different Types of Warehouse Shelving

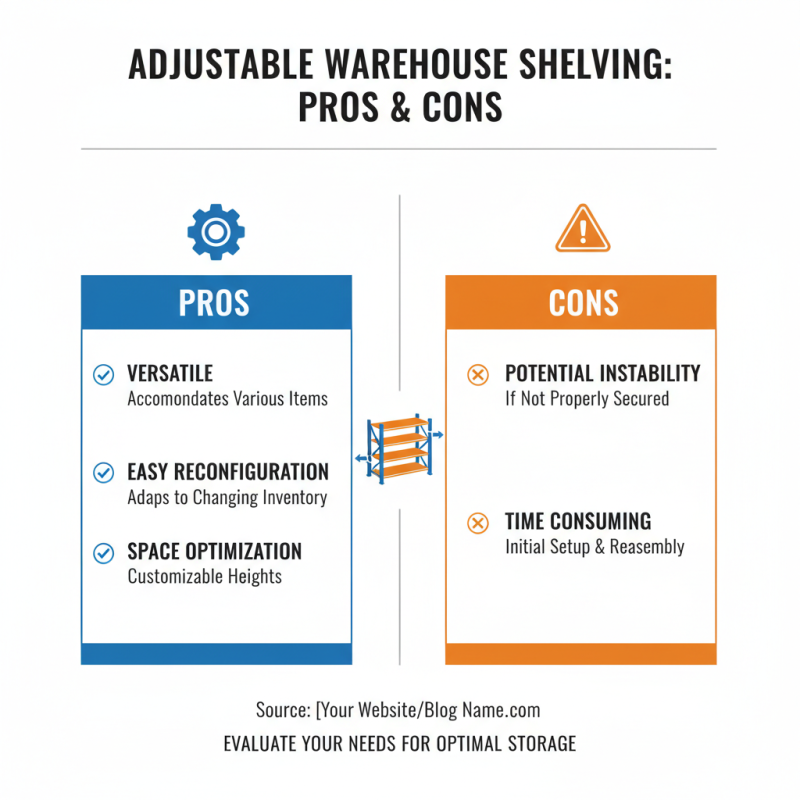

When evaluating different types of warehouse shelving, it's essential to consider the specific needs of your space. Adjustable shelving is versatile and can accommodate various items. It allows for easy reconfiguration, which is valuable if your inventory changes frequently. However, this flexibility can sometimes lead to instability if not properly secured.

Heavy-duty shelving is another common choice. It's designed to support substantial weight. This type is ideal for storing bulk items and heavy machinery. However, it often requires more floor space, which can be a challenge in smaller warehouses. Balancing weight distribution is crucial to avoid accidents.

Pallet racking is popular for large inventory loads. It maximizes vertical space and improves accessibility. Yet, it can be costly to install and maintain. Also, it may not be the best fit for lighter items. A careful assessment of your inventory and layout is necessary. It's vital to consider the potential drawbacks of each shelving option. This will ultimately lead you to make an informed decision.

Considerations for Weight Capacity and Stability

When selecting warehouse shelving, weight capacity and stability are critical factors. Industry data shows that approximately 60% of warehouse accidents occur due to improper shelving use. Understanding weight limits is essential for preventing injuries. A shelf that cannot support the designated load may collapse.

Consider that heavy items need sturdy shelving. Metal shelving usually offers higher weight capacities than wood or plastic. For instance, heavy-duty metal shelves can often support over 2,000 pounds per shelf, making them ideal for heavy machinery or bulk storage. It is essential, however, to ensure that the floor can also handle the total load.

Stability is another crucial aspect. Shelves must remain upright under heavy loads and during fork-lift operations. A study revealed that nearly 30% of all shelf collapses are linked to instability issues. Ensuring proper anchoring can mitigate this risk. Regular inspections and maintenance will help identify any weak points in your shelving system. Choosing the right configuration and materials can make a significant difference in safety and efficiency.

Assessing Space and Layout Needs in Your Warehouse

When assessing space and layout needs in your warehouse, start with a thorough evaluation. Measure your floor space carefully. Understand the height of your ceilings. This information is crucial. Different shelving types require varying heights. Visualize how you want to organize products. Will it be by size, type, or frequency of use?

Tips: Create a detailed sketch of your warehouse layout. Think about pathways. Ensure it's easy to access high shelves. Avoid overcrowding. This might make it difficult to retrieve items. Planning is key to efficiency. Consider future growth and flexibility in your layout.

Also, think about the weight capacity of your shelves. Heavier items need sturdier shelving. If your current layout doesn’t fit well, reflect on your design. It’s okay to adjust. Sometimes, a simple reorganization can significantly improve workflow. Don’t overlook the importance of employee movement. Everyone should have room to work comfortably.

Budgeting for Warehouse Shelving Solutions

When budgeting for warehouse shelving solutions, it's crucial to consider various factors. Start by assessing your specific needs. Think about the types of products you will store. Will they be heavy, bulky, or small? This directly impacts the shelving type and material required.

Next, identify your available budget. Shelving can range from economical to high-end options. Consider all potential costs, including installation and maintenance. Miscalculating can lead to overspending. It’s essential to balance quality with price. Sometimes, investing a bit more upfront can save costs in the long run.

Don’t overlook the importance of space efficiency. Measure your warehouse dimensions accurately. Improper measurements can lead to empty spots or overcrowding. This wasted space affects productivity. Regular reflection on your choices can help you adjust as needs evolve.

Related Posts

-

How to Choose the Best Industrial Storage Solutions for Your Business Needs

-

How to Choose the Right Commercial Racking System for Your Business Needs

-

Top 10 Industrial Racking Solutions to Optimize Your Warehouse Space

-

Top 10 Industrial Storage Solutions to Optimize Your Warehouse Space

-

How to Choose the Right Warehouse Pallet Racks for Your Business Needs

-

Why Heavy Duty Racking is Essential for Efficient Warehouse Storage Solutions