Blog

How to Choose the Right Warehouse Storage Racks for Your Needs?

Choosing the right warehouse storage racks is crucial for optimizing space and efficiency. According to a recent report by the Warehousing Education and Research Council (WERC), effective storage systems can increase warehouse productivity by 30%. This statistic highlights the importance of selecting appropriate storage solutions tailored to specific needs.

Expert John Smith, a leader in warehouse operations, states, “Choosing the right storage racks is not just about space; it’s about enhancing workflow.” His insight underscores the importance of aligning rack types with inventory flow. For instance, selective racks are ideal for facilities with diverse products, while pallet flow racks suit high-volume operations.

However, many businesses overlook these aspects. Some settle for cheaper options, sacrificing quality for initial savings. This flawed approach can lead to inefficiencies and increased costs in the long run. The right warehouse storage racks can profoundly impact overall operations, making informed decisions vital for success. Reflecting on these factors is essential for warehouse managers aiming to maximize their facility's potential.

Understanding Your Storage Requirements

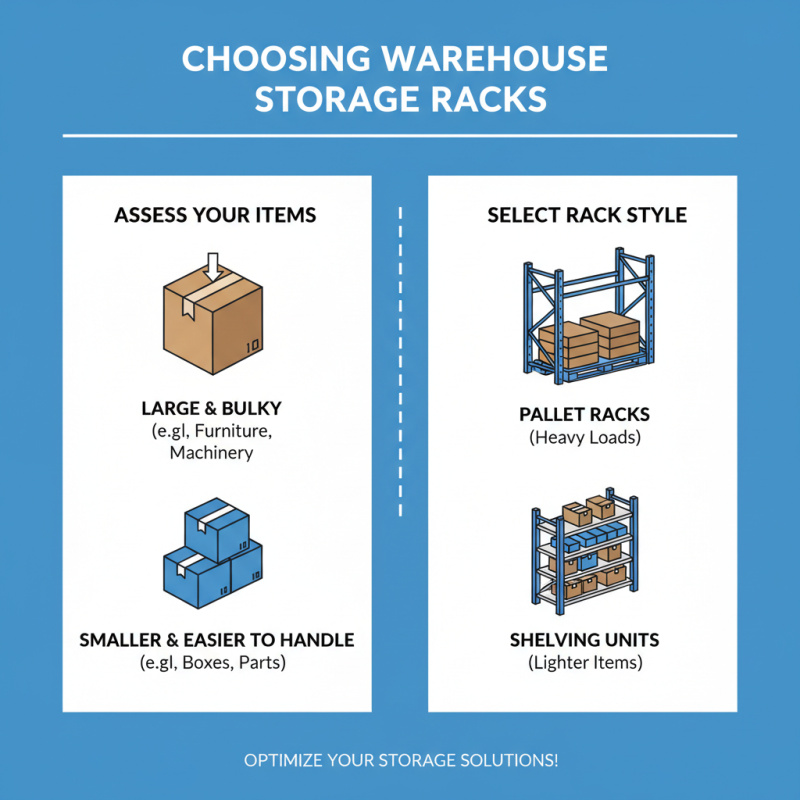

Understanding your storage requirements is essential when choosing the right warehouse storage racks. Start by assessing the types of items you need to store. Are they large and bulky? Or are they smaller, easier to handle? Knowing this will help you decide on the appropriate rack style. For instance, pallet racks are suitable for heavy loads, while shelving units work well for lighter items.

Consider the weight capacity you need. Each rack has a limit. Failing to account for this can lead to accidents and damage. You might want to measure your items’ dimensions too. This can be a tedious process, but it helps ensure everything fits well. Even small discrepancies can create big issues down the line.

Think about the layout of your warehouse. Is there enough space to navigate? Will you need additional height? Sometimes, aspiring for more storage can lead to overcrowded aisles. It’s easy to overlook these aspects when focused solely on capacity. Always reflect on how the racks will work for your unique needs. Staying adaptive and attentive is key to effective storage solutions.

Evaluating Different Types of Storage Racks

When evaluating different types of storage racks, consider your inventory type. Pallet racks are great for bulky goods. They allow for easy access. Imagine rows of products stacked high. But what if your items are smaller, like boxes or tools? In that case, shelving systems work better. Adjustable shelves can accommodate a variety of heights.

Another option is cantilever racks. These are ideal for long items like lumber or pipes. They provide stability and accessibility. Yet, they take up more floor space than you might expect. Don't overlook wire racks either. They are flexible and often easier to clean. But can they hold your heavier items?

Think about your workflow as well. If items move frequently, choose racks that allow for quick loading and unloading. Consider the weight limit of each rack type. If you ignore this, it could lead to accidents. A careful balance of function and safety is essential in your decision-making process. Choose wisely. The right rack system can significantly enhance your efficiency.

Assessing Weight Capacity and Durability Needs

Choosing the right warehouse storage racks is crucial for efficiency. Assessing weight capacity and durability is a key factor. Each rack should support the load you plan to store. Overloading can lead to accidents or damaged goods. Check the specifications of the racks carefully.

Durability is equally important. Think about the materials used. Steel is often strong and long-lasting. However, not all steel is the same. Consider factors like rust resistance for warehouses in humid areas. Plastic racks might be lighter but may not handle heavy loads well. Be aware of your warehouse environment when making choices.

It's easy to overlook these details. Sometimes, a visually appealing rack can be misleading. You might need to adjust your choices based on past experiences. Reflect on what has worked and what hasn’t. This can lead to better decisions in the future. Customize your racks based on your specific needs. Prioritize both weight capacity and durability for optimal performance.

How to Choose the Right Warehouse Storage Racks for Your Needs? - Assessing Weight Capacity and Durability Needs

| Rack Type | Weight Capacity (lbs) | Material | Durability Rating | Ideal Use |

|---|---|---|---|---|

| Selective Pallet Racks | 2,500 - 3,000 | Steel | High | Warehouse Operations |

| Drive-in Racks | 3,000 - 5,000 | Steel | Very High | Bulk Storage |

| Cantilever Racks | 1,500 - 10,000 | Steel | High | Long or Irregular Items |

| Adjustable Racks | 1,000 - 2,500 | Metal/Plastic | Moderate | Versatile Storage |

Considering Space Efficiency and Layout Design

When choosing warehouse storage racks, layout design is critical. Assess your available space carefully. Consider the height, width, and depth of your racks. You want to maximize vertical space without making it hard to access items. A well-thought-out layout can significantly improve efficiency. Think about the flow of movement in your warehouse.

Analyze how products move in and out. Narrow aisles can save space, but they may slow down operations. Wider aisles improve access but require more room. Determine the best balance for your needs. Visual tools, like drawings or software, help in planning. They make it easier to visualize stack placements and traffic patterns.

Don’t forget about safety. Ensure racks are stable and meet storage requirements. Overcrowding shelves can lead to accidents. Also, reflect on your future needs. Will your inventory grow? Room for expansion is wise. Planning ahead can save costs later. Adjusting the layout after installation can be a hassle. Solid planning at the start pays off.

Warehouse Storage Racks Efficiency Analysis

Budgeting and Cost-Effectiveness in Rack Selection

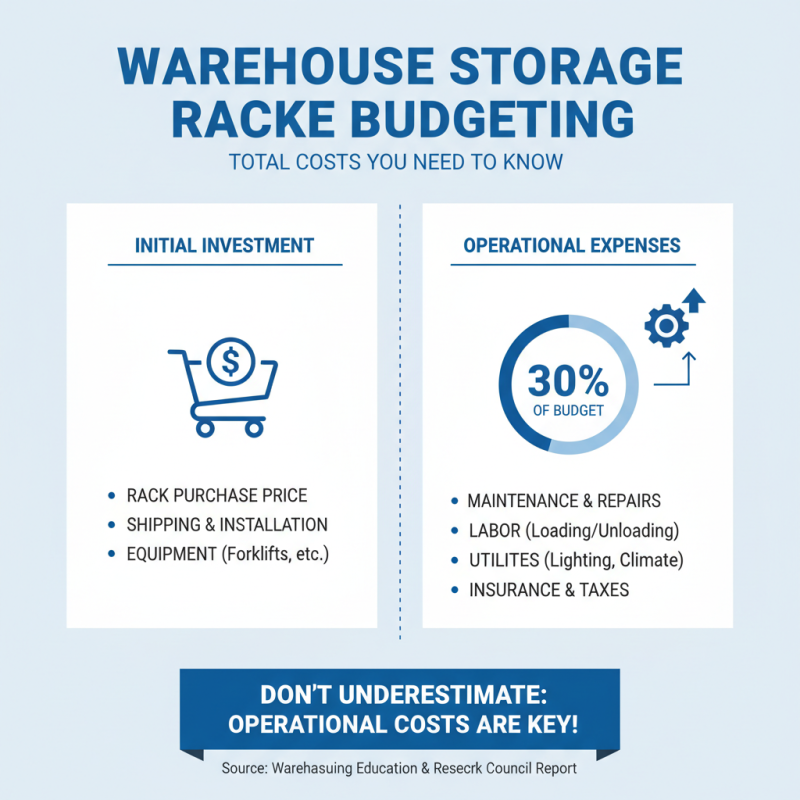

When selecting warehouse storage racks, budgeting is crucial. Many businesses underestimate total costs. According to a recent report by the Warehousing Education and Research Council, operational expenses can account for up to 30% of warehouse budgets. This makes understanding the cost of racks essential.

Consider the initial purchase price and long-term durability. Metal racks may be pricier upfront, yet they often offer better longevity. A cost-effective solution today could lead to higher expenses down the road. In fact, studies show that a 10% increase in quality can extend rack lifespan by nearly 50%. This implication is vital for warehouse managers planning budgets.

Remember to think beyond just rack expenses. There are installation costs, maintenance, and potential disruptions during assembly. Allocating funds for potential unforeseen expenses can prevent financial strain later. An often overlooked factor is safety compliance, which, if ignored, can lead to hefty fines. Always seek to balance cost and functionality in your selection process.

Related Posts

-

Top 5 Benefits of Using Warehouse Shelving Racks for Efficient Storage Solutions

-

How to Choose the Right Warehouse Pallet Racks for Your Business Needs

-

Why Heavy Duty Racking is Essential for Efficient Warehouse Storage Solutions

-

Why You Should Choose Heavy Duty Storage Racks for Your Garage or Warehouse

-

How to Choose the Right Commercial Racking System for Your Business Needs

-

How to Optimize Industrial Storage Solutions for Maximum Efficiency