Blog

Top 10 Industrial Racking Solutions to Optimize Your Warehouse Space

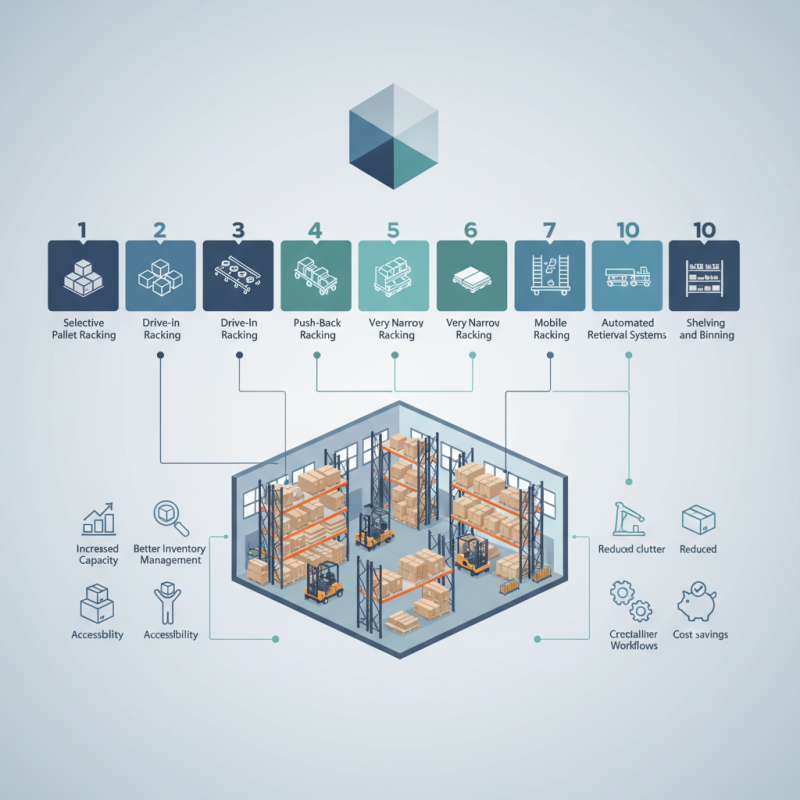

In today's fast-paced industrial landscape, efficient space management is crucial for maximized operational productivity. One of the most effective ways to enhance warehouse efficiency is through the implementation of optimized industrial racking solutions. These systems not only improve the storage capacity of your warehouse but also enable better inventory management and accessibility. With the right industrial racking in place, businesses can dramatically reduce clutter, streamline workflows, and ultimately save on costs associated with space limitations.

This article will explore the top 10 industrial racking solutions designed to transform your warehouse into a more organized and functional space. From traditional pallet racks to innovative storage systems, each option offers unique benefits tailored to various storage needs and warehouse layouts. By understanding these solutions, warehouse managers can make informed decisions that align with their operational goals, leading to enhanced efficiency and productivity. Whether you're looking to optimize a small storage area or revamp a large warehouse, these industrial racking options will provide valuable insights for maximizing your available space.

Key Factors to Consider When Choosing Industrial Racking Solutions

When selecting industrial racking solutions, there are several key factors that warehouse managers should take into account to ensure maximum efficiency and safety. First, understanding the specific storage requirements of the warehouse is crucial. For example, the layout, types of products stored, and velocity of inventory all play significant roles in determining the most appropriate racking system. According to a report by the Material Handling Industry of America, optimizing warehouse space can lead to an increase in storage capacity by up to 30% while improving picking efficiency by nearly 20%.

Another important consideration is the load capacity of the racking systems. Each type of racking comes with its own specifications regarding weight distribution and the types of goods that can be stored safely. A study from the American Warehouse Association emphasizes that using improperly configured racking units can lead to structural failures, costing companies both in terms of repair expenses and potential liability issues. Therefore, assessing the weight limits and ensuring that the racking system aligns with the operational demands is essential for maintaining a safe and functional warehouse environment.

Furthermore, adaptability and future scalability should be integral factors in the decision-making process. As businesses evolve, so do their storage needs. A report from Logistics Management indicates that warehouses that invest in flexible racking solutions can better accommodate fluctuations in product lines or seasonal variations in inventory. This adaptability not only enhances productivity but also allows for more effective space management over time, ensuring that the warehouse can grow alongside the business without significant overhaul costs.

Top 10 Industrial Racking Solutions to Optimize Your Warehouse Space

| Racking Type | Load Capacity (lbs) | Height (ft) | Depth (in) | Recommended Use |

|---|---|---|---|---|

| Selective Rack | 2,500 | 12 | 48 | General Storage |

| Drive-in Rack | 3,000 | 15 | 42 | High-Density Storage |

| Pallet Flow Rack | 2,000 | 12 | 48 | FIFO Storage |

| Push-back Rack | 2,500 | 14 | 42 | Bulk Storage |

| Cantilever Rack | 1,500 | 16 | 30 | Long Items Storage |

| Double Deep Rack | 2,800 | 15 | 48 | High Storage Efficiency |

| Mobile Rack | 1,800 | 10 | 36 | Flexibility in Configuration |

| Shelf Rack | 800 | 8 | 24 | Lightweight Storage |

| Rack Supported Mezzanine | 2,000 | 20 | 60 | Maximize Vertical Space |

| Boltless Rack | 1,200 | 10 | 36 | Easy Assembly |

Types of Racking Systems Suitable for Different Warehouse Needs

When it comes to optimizing warehouse space, selecting the right racking system is crucial for efficiency and accessibility. There are several types of racking systems tailored to meet specific warehouse needs, each designed to enhance storage capabilities while ensuring ease of inventory management. For example, selective racking systems provide direct access to pallets and are ideal for warehouses with a wide variety of products. These systems allow for straightforward organization, making them suitable for businesses with fluctuating stock levels or diverse product ranges.

On the other hand, drive-in and drive-thru racking systems maximize vertical space and are well-suited for high-density storage requirements. By allowing forklifts to drive directly into the racking system, these solutions minimize aisle space and enhance storage density. Additionally, pallet flow racking is perfect for first-in, first-out (FIFO) inventory management, ensuring that older stock is accessed before new arrivals. This type of racking is particularly beneficial for perishable goods or products with expiry dates, allowing for smooth transitions and improved stock rotation. Selecting the right racking solution based on specific operational needs can significantly enhance warehouse productivity and space efficiency.

Benefits of Optimized Racking Systems in Warehouse Efficiency

Optimizing racking systems within a warehouse plays a crucial role in enhancing overall operational efficiency. According to a report by the Warehousing Education and Research Council (WERC), effective use of space can increase storage capacity by up to 30%, allowing companies to store more products without the need for additional square footage. This optimization not only reduces operational costs associated with expanding warehouse space but also improves order fulfillment speed, contributing to higher customer satisfaction.

Moreover, an optimized racking system can significantly impact workforce productivity. A study from the Material Handling Industry of America (MHIA) indicates that implementing efficient racking solutions can boost employee productivity by as much as 20%. This increase is primarily attributed to the streamlined accessibility of goods, which minimizes the time spent searching for items and reduces the risk of injury from manual handling. As warehouses continue to evolve, the integration of advanced racking systems not only maximizes space utilization but also enhances safety and operational workflows, leading to a more responsive supply chain.

Top 10 Industrial Racking Solutions to Optimize Your Warehouse Space

This chart depicts the effectiveness of different industrial racking solutions in optimizing warehouse space, showcasing the average space utilization percentage for each method.

Best Practices for Implementing Industrial Racking Solutions

Implementing effective industrial racking solutions is essential for optimizing warehouse space and improving operational efficiency. One of the best practices is to conduct a thorough assessment of the warehouse layout. Understanding the flow of goods and the types of products stored will allow for tailored racking solutions that maximize available space. Consider factors such as access frequency, load-bearing requirements, and safety standards to ensure that the racking system meets operational needs while adhering to industry regulations.

Another best practice involves employee training and involvement in the racking implementation process. Engaging warehouse staff not only fosters a sense of ownership but also enhances safety and efficiency. Providing training on proper loading techniques and safety procedures will minimize accidents and damage to goods. Regular audits and feedback loops can be established to refine the racking system and address any emerging issues promptly, ensuring that the racking solution continues to meet the evolving demands of the warehouse environment.

Maintenance and Safety Tips for Warehouse Racking Systems

When managing warehouse racking systems, maintenance and safety are top priorities that cannot be overlooked. According to a report from the Industrial Storage Equipment Association (ISEA), nearly 70% of workplace injuries can be attributed to improper storage practices. Regular inspections of racking systems are crucial to identifying any potential safety hazards, such as damaged beams, bent uprights, or loose connections. Establishing a routine maintenance schedule not only extends the lifespan of racking systems but also ensures a safer work environment for employees.

Moreover, adhering to safety guidelines is imperative for operational efficiency. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of proper loading practices, which include adhering to weight limits and ensuring even weight distribution on shelves. Implementing safety training programs can significantly reduce accidents; a study by SafeWork Australia revealed that organizations investing in safety training reported a 30% decrease in incidents. Additionally, clearly marking racking systems with load limits and utilizing safety barriers can help prevent accidents and ensure compliance with safety regulations. Engaging employees in safety initiatives fosters a culture of awareness and responsibility, ultimately enhancing overall warehouse safety.

Related Posts

-

Top 10 Racking System Solutions for Optimal Warehouse Efficiency

-

How to Choose the Best Industrial Storage Solutions for Your Business Needs

-

Top 10 Industrial Storage Solutions to Optimize Your Warehouse Space

-

Top 5 Best Cantilever Racking Systems for Maximizing Storage Efficiency

-

Top 10 Warehouse Racking Systems to Maximize Space and Efficiency

-

How to Choose the Right Warehouse Pallet Racks for Your Business Needs