Blog

Why Are Industrial Storage Racks Essential for Efficient Warehouse Management?

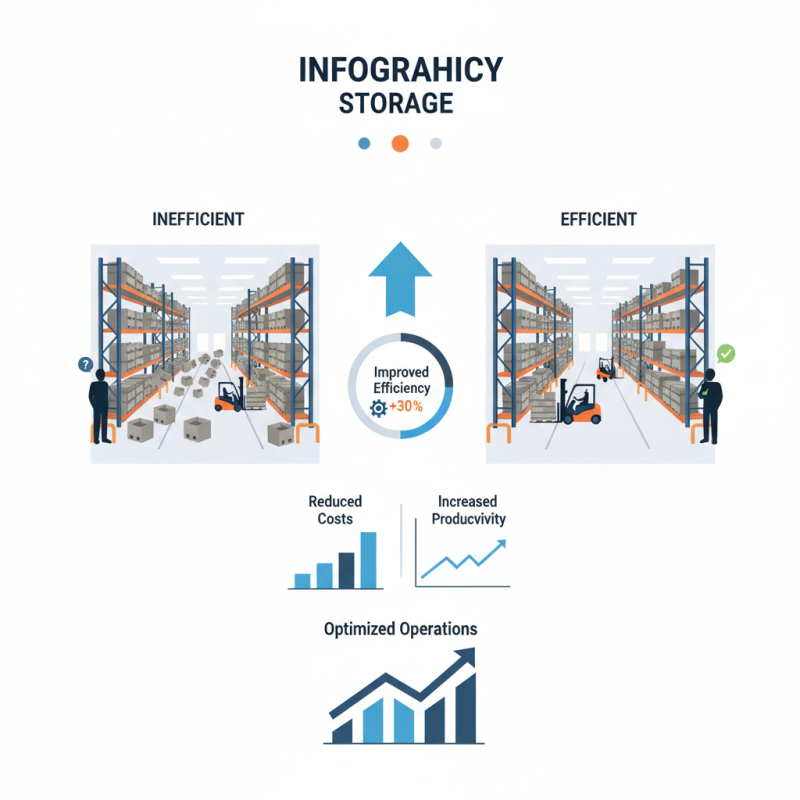

Efficient warehouse management is crucial for any thriving business. The role of industrial storage racks cannot be overstated in this context. According to a report by the Warehousing Education and Research Council (WERC), effective storage solutions can improve warehouse efficiency by up to 30%. This statistic emphasizes how vital proper storage is in meeting organizational demand.

John Smith, a recognized expert in warehouse management, states, "Industrial storage racks transform chaotic spaces into structured zones." His insight highlights the importance of organization in warehouse operations. Without appropriate racks, businesses risk losing inventory and time, leading to possible revenue loss.

Imagine a warehouse with overflowing aisles and boxed inventory stacked haphazardly. Such chaos diminishes productivity. Companies must rethink their storage strategies to prevent bottlenecks. In contrast, a well-organized warehouse, supported by industrial storage racks, fosters operational efficiency. Addressing these challenges is vital for companies striving to excel in a competitive market.

The Importance of Industrial Storage Racks in Warehouse Efficiency

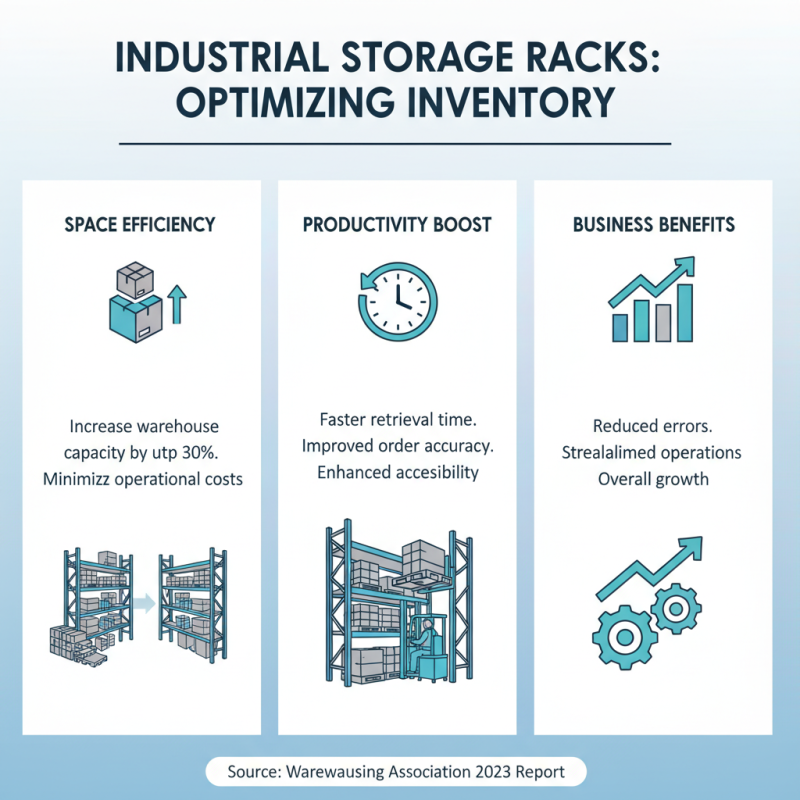

In the realm of warehouse management, the role of industrial storage racks cannot be overstated. A recent industry report revealed that efficient use of space can increase warehouse productivity by up to 30%. This is significant. Well-designed storage racks optimize vertical space. They allow for better organization and faster retrieval of products.

Improper storage can lead to chaos. Employees waste time searching for items lost in a cluttered environment. A study by the Warehousing Education and Research Council found that cluttered warehouses can reduce efficiency by 25%. Investing in effective storage solutions is essential. Not only do racks streamline operations, but they also enhance employee safety. When products are stored properly, the risk of accidents decreases.

However, not every warehouse utilizes racks optimally. Many operations overlook training for staff on proper use. Others fail to assess their specific needs, leading to the wrong choices in rack types. This can result in wasted space and resources. Continuous evaluation of storage systems is necessary. It helps warehouses adapt to changing inventory needs and improve overall efficiency.

How Storage Racks Optimize Space Utilization in Warehousing

In modern warehousing, optimally using space is crucial. Storage racks provide an effective solution to maximize vertical and horizontal storage. By utilizing shelving and pallet racks, warehouses can significantly increase their storage capacity. This allows for better organization and easier access to products. Higher tiers can accommodate more items, freeing up floor space for operational activities.

However, not all storage solutions are effective in every setting. A poorly designed rack system can lead to wasted space. Some items may not fit well or become difficult to retrieve. Regular assessment of inventory and storage methods is necessary. This helps ensure that the racks align with the evolving needs of the warehouse.

Additionally, the arrangement of items on the racks influences efficiency. Commonly used items should be stored at eye level for easy access. If everything is not organized well, retrieval can become time-consuming. This not only affects productivity but can also lead to frustration among staff. Regular training on best practices is essential for maintaining an efficient warehouse.

Warehouse Space Utilization by Storage Rack Type

This chart illustrates the effectiveness of different types of industrial storage racks in optimizing space utilization within warehouses. As shown, pallet racking and shelving systems contribute significantly to maximizing storage capacity compared to other types.

The Role of Industrial Racks in Enhancing Inventory Management Practices

Industrial storage racks play a pivotal role in optimizing inventory management. Efficient use of space helps businesses minimize operational costs. According to a 2023 report by the Warehousing Association, effective racking can increase warehouse capacity by up to 30%. The right storage solution enhances product accessibility, speeds up retrieval time, and improves order accuracy. This can bolster overall productivity.

However, many warehouses still struggle with underutilized space. Poorly designed layouts often lead to inefficiencies. For example, 45% of warehouse managers report issues with inventory accuracy due to outdated shelving systems. This is a significant problem. Racks should be regularly assessed to match current inventory needs. A well-organized warehouse can reduce labor costs and lead to faster delivery times.

Investing in strong, versatile racks is crucial. They should accommodate different products and sizes. Furthermore, regular evaluations can identify areas for improvement. Ignoring these factors can result in lost revenue. In a competitive market, every inch of space matters. The future of warehouse management depends on maximizing existing resources while minimizing waste.

Impact of Different Rack Types on Warehouse Productivity and Operations

Warehouse productivity hinges on the choice of storage racks. Different rack types impact organization and efficiency. A well-structured warehouse can increase inventory access by 30%. Auxiliary racks enhance space utilization, allowing for more products in a compact area. According to industry reports, leveraging selective racks can boost picking efficiency by 20-30%.

Drive-in racks present challenges. These racks allow high-density storage but can complicate inventory management. Pushing products deep into the rack makes retrieval difficult. Traditional pallet racks offer better access but may waste vertical space. Many warehouses struggle to find the right balance between density and accessibility.

Considerable flexibility exists in designs. A mix of rack types may serve various needs. However, improper use may lead to congestion. Employees could spend extra time searching for products. Streamlining layout is essential to optimize operations. Investing in the right rack systems might yield significant returns, yet it's crucial to assess your unique requirements.

Why Are Industrial Storage Racks Essential for Efficient Warehouse Management?

| Rack Type | Storage Capacity (kg) | Space Efficiency (%) | Accessibility Level | Ideal Use Case |

|---|---|---|---|---|

| Selective Pallet Racks | 1,500 | 60 | High | General warehousing, retail |

| Drive-In Racks | 2,000 | 80 | Medium | Bulk storage of homogenous items |

| Push Back Racks | 1,800 | 75 | Medium | Dynamic storage of multiple SKUs |

| Mobile Racking | 1,200 | 90 | Low | High-density storage |

| Shelf Racks | 800 | 50 | High | Small items, hand-picking |

Statistics on Cost Savings from Effective Rack Systems in Warehouses

Efficient warehouse management directly impacts the bottom line. According to a study by Peerless Research Group, optimized rack systems can save companies up to 30% in operational costs. These savings come from enhanced space utilization and reduced labor hours. With proper rack systems, warehouses can store more products in less space, effectively increasing capacity without major investments.

Data from the Warehouse Education and Research Council indicates that effective racking systems improve inventory accuracy by 25%. This accuracy leads to fewer stockouts and overstock situations, saving money on emergency orders and storage costs. Companies with well-organized storage racks often report increased productivity. Workers spend less time searching for items. Time is valuable; therefore, efficient layouts matter.

Tip: Conduct regular assessments of your racking system. Identify areas that need improvement. Small adjustments can lead to noticeable changes in efficiency.

Tip: Train employees on the correct use of storage racks. Ensure they understand the layout. This knowledge can prevent accidents and misuse.

In a world where space and efficiency are paramount, investing in industrial storage racks is more than a trend. It's a necessity for sustained growth.

Related Posts

-

Top 5 Benefits of Using Warehouse Shelving Racks for Efficient Storage Solutions

-

Top 5 Best Cantilever Racking Systems for Maximizing Storage Efficiency

-

Why Heavy Duty Racking is Essential for Efficient Warehouse Storage Solutions

-

How to Choose the Right Commercial Racking System for Your Business Needs

-

Ultimate Guide to Choosing the Best Pallet Shelving for Your Warehouse in 2025

-

2026 Best Racking System Solutions for Efficient Storage Management?