Blog

10 Essential Tips for Maximizing Warehouse Shelving Efficiency

In the fast-paced world of logistics and supply chain management, the efficiency of warehouse shelving plays a critical role in overall operational success. According to John Smith, a renowned expert in warehouse operations and author of "Optimizing Storage Solutions," “Effective warehouse shelving is not just about maximizing space; it’s about enhancing accessibility and workflow efficiency.” As businesses strive to meet the growing demands of e-commerce and instantaneous delivery, understanding the intricacies of warehouse shelving becomes paramount.

Maximizing warehouse shelving efficiency involves more than just stacking items high or cramming as much as possible into a space. It requires a strategic approach that incorporates best practices, innovative storage solutions, and a keen understanding of inventory management. By implementing smart shelving systems, warehouse managers can not only improve space utilization but also streamline picking processes and reduce handling times, leading to improved service levels and cost savings.

This article presents ten essential tips for optimizing warehouse shelving efficiency, providing insights that can help businesses enhance their storage capabilities and adapt to the evolving landscape of warehousing. Whether you are managing a small distribution center or a large-scale warehouse, these strategies can help you create a more organized and productive space, ultimately contributing to your bottom line.

Understanding Warehouse Shelving Types and Their Applications

When it comes to warehouse efficiency, understanding the various shelving types and their applications is crucial. Different shelving designs serve unique purposes, catering to diverse operational needs. For instance, selective pallet racking is one of the most common types, allowing direct access to each pallet, which enhances retrieval times. According to a recent industry report by the Material Handling Industry of America (MHIA), nearly 35% of warehouses utilize this system due to its flexibility and ease of use, maximizing space and productivity.

In contrast, drive-in and drive-thru racking systems are engineered for high-density storage, making them ideal for perishable goods or bulk items. A survey conducted by Peerless Research Group indicated that businesses employing high-density systems often experience a 20% reduction in costs associated with storage space. Furthermore, mobile shelving systems, which allow units to move on tracks, can increase storage capacity by up to 50% compared to static shelving. By analyzing the specific needs of the warehouse and choosing the right shelving type, businesses can significantly boost their operational efficiency and overall productivity.

Assessing Your Warehouse Space for Optimal Shelving Arrangement

When it comes to maximizing warehouse shelving efficiency, the first step lies in thoroughly assessing and understanding your warehouse space. A recent industry report from the Warehouse Efficiency Institute highlighted that a well-planned shelving arrangement can increase storage capacity by up to 30%. This statistic illustrates the importance of optimizing the layout according to the specific dimensions and flow of your warehouse. By carefully examining the available space, you can identify areas that might be underutilized or suitable for different types of shelving solutions, ultimately contributing to enhanced operational effectiveness.

Moreover, incorporating data-driven strategies into your shelving assessment can yield significant benefits. For instance, the National Institute of Standards and Technology (NIST) suggests utilizing simulations based on the dimensions and inventory turnover rates to determine the most effective shelving configurations. This approach not only aids in maximizing space but also ensures that high-turnover items are easily accessible, thus reducing picking times. Implementing such methodologies will not only increase efficiency but also optimize inventory management, ensuring that warehouse operations align with contemporary demands, ultimately leading to cost savings and improved service levels.

Implementing Advanced Inventory Management Techniques

Implementing advanced inventory management techniques is crucial for maximizing warehouse shelving efficiency. According to the 2023 Warehouse Management System (WMS) report by the Supply Chain Institute, companies that utilize real-time inventory tracking can reduce stock discrepancies by up to 30%. This level of precision not only streamlines shelving arrangement but also enhances the sales process by ensuring that items are readily available when needed.

Employing technologies such as barcoding and RFID tags significantly improves inventory accuracy and assists in effective space management within the warehouse.

Moreover, integrating automated inventory management software can lead to notable improvements in warehouse operations. The 2022 Logistics Trends Report indicates that warehouses employing automated systems see an average increase in picking efficiency of 25%. This is largely due to reduced manual errors and the ability to forecast inventory needs more accurately.

For example, predictive analytics can assess historical data and identify trends, enabling warehouses to optimize stock levels and shelf arrangement accordingly. By aligning inventory management with advanced technology, warehouses can enhance both operational efficiency and customer satisfaction.

Utilizing Vertical Space for Maximum Storage Efficiency

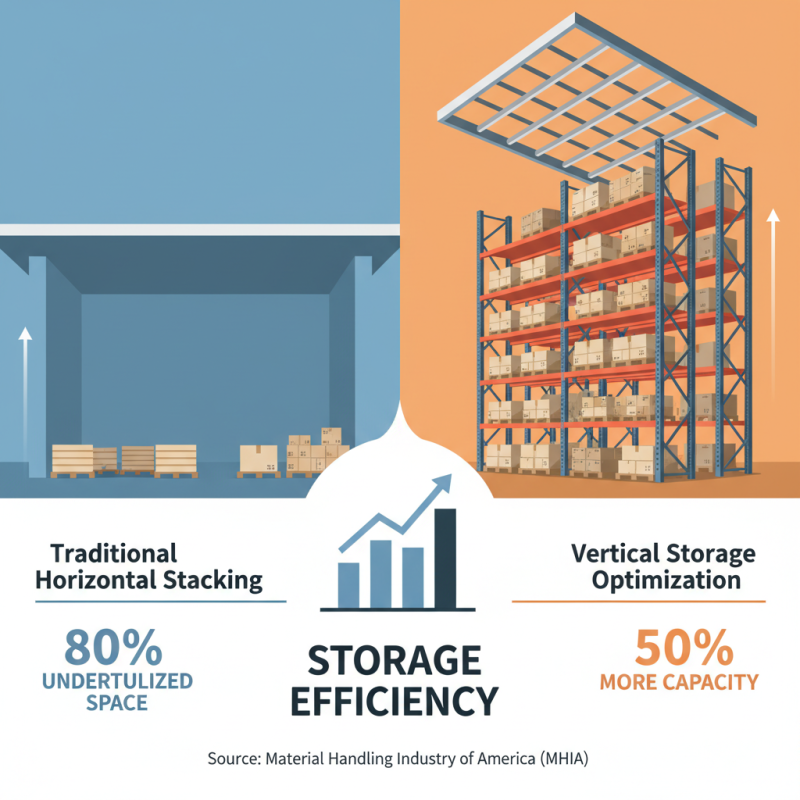

Utilizing vertical space in a warehouse is critical for boosting storage efficiency and optimizing operations. According to the Material Handling Industry of America (MHIA), over 80% of warehouse space is underutilized due to horizontal stacking. By harnessing vertical dimensions, facilities can increase storage capacity significantly without the need for expanding floor space. For instance, racking systems can often be configured to allow for vertical storage heights of up to 30 feet, depending on the facility and inventory type. This adaptation enables businesses to achieve a nearly 50% increase in usable storage compared to traditional shelving methods.

Moreover, maximizing vertical space not only enhances storage capacity but also improves accessibility and organization within the warehouse. The Warehousing Education and Research Council (WERC) notes that optimized shelving systems can reduce picking times by up to 20%. This efficiency is particularly vital in fast-paced environments where time and accuracy directly affect customer satisfaction. By implementing vertical storage solutions like high-bay racking or multi-tier shelving, warehouses can streamline their workflow and ensure that products are readily available, minimizing operational bottlenecks. Investing in vertical space is not merely a trend; it is a foundational strategy that can lead to substantial operational improvements and cost savings in the long run.

Regular Maintenance and Reorganization of Shelving Systems

Regular maintenance and reorganization of shelving systems are vital components for maximizing warehouse shelving efficiency. Industry studies reveal that warehouses optimizing their shelving layouts can enhance storage capacity by up to 30%. Regular inspections of shelving units not only help identify potential safety hazards but also ensure that the layout remains conducive to the efficient movement of goods. According to a report from the Warehousing Education and Research Council, routine maintenance activities, including tightening loose screws and checking for structural integrity, can significantly prolong the lifespan of shelving systems, which can save companies thousands in replacement costs.

Reorganization of shelving is equally important, particularly as inventory levels change. The introduction of a dynamic shelving system that adapts to fluctuating product sizes and turnover rates can result in more efficient space utilization, ultimately leading to improved productivity. Data suggests that reorganizing shelving every six months can boost picking efficiency by 20% by reducing travel time for workers. Implementing a first-in-first-out (FIFO) system in combination with regular audits ensures that items are picked in an order that reduces spoilage and increases turnover, further enhancing overall warehouse performance.

Related Posts

-

10 Best Racking and Shelving Solutions for Efficient Storage Management

-

2025 Guide: How to Efficiently Rack Shelves for Maximum Space Utilization

-

How to Choose the Right Industrial Racking for Your Warehouse Needs

-

Why You Should Choose Heavy Duty Storage Racks for Your Garage or Warehouse

-

Top Heavy Duty Racking Systems for Efficient Warehouse Storage in 2025

-

How to Optimize Industrial Storage Solutions for Maximum Efficiency