Blog

How to Optimize Industrial Storage Solutions for Maximum Efficiency

In the ever-evolving landscape of manufacturing and logistics, optimizing industrial storage solutions has become a critical focus for enterprises seeking to enhance operational efficiency. According to a recent report by the Warehousing Education and Research Council, businesses can reduce operational costs by up to 30% through streamlined storage practices and effective inventory management. With the global industrial storage market projected to reach $60 billion by 2026, the importance of maximizing storage efficiency cannot be overlooked.

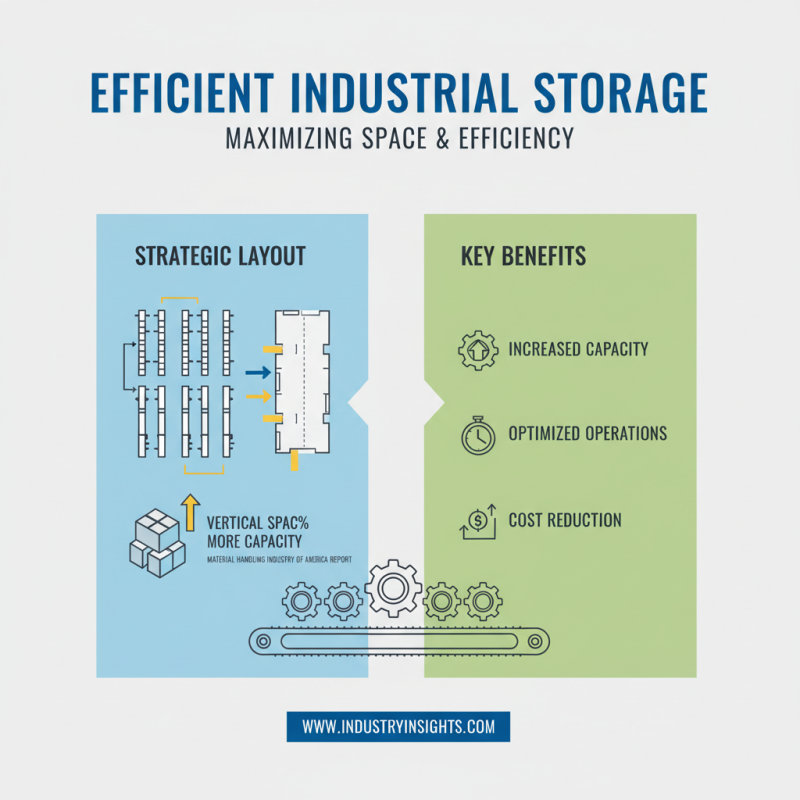

Furthermore, the increasing complexities of supply chain logistics demand innovative approaches to industrial storage. The implementation of automation and smart technologies has shown to improve inventory accuracy and reduce pick times significantly. A study from the Material Handling Industry of America indicates that automation can lead to a reduction in labor costs by 20-30%, thus positioning automated storage solutions as a viable option for companies striving to meet growing consumer demands while maintaining high levels of productivity.

To remain competitive, businesses must adopt best practices in industrial storage, including space optimization, inventory categorization, and the incorporation of technology. By doing so, they not only enhance their operational capabilities but also contribute to sustainable practices by minimizing wasted resources and maximizing space utilization throughout the supply chain.

Understanding Industrial Storage Needs and Challenges

Understanding industrial storage needs and challenges involves recognizing the complexities of modern supply chains and the increasing demand for space efficiency. According to a report by the Warehousing Education and Research Council (WERC), nearly 75% of warehouses report that they struggle with space constraints, which hampers their ability to operate efficiently. This challenge is exacerbated by the rising costs of real estate, compelling businesses to optimize their storage solutions strategically. Understanding the specific storage requirements based on the type of goods, their turnover rates, and seasonal demands is critical to addressing these issues effectively.

Moreover, operational challenges such as inventory inaccuracies and inefficiencies in retrieval processes hinder optimal storage utilization. A study by the Material Handling Institute indicates that nearly 30% of businesses experience inventory discrepancies, resulting in wasted labor and slowed workflow. Implementing technologies such as automated storage systems and real-time inventory tracking can mitigate these challenges, allowing companies to maximize their available space and improve their overall efficiency. Streamlining the layout and considering modular storage solutions also play a vital role in enhancing accessibility and reducing operational bottlenecks. By addressing these needs, companies can better align their storage capabilities with business goals and operational demands.

Key Principles for Designing Efficient Storage Solutions

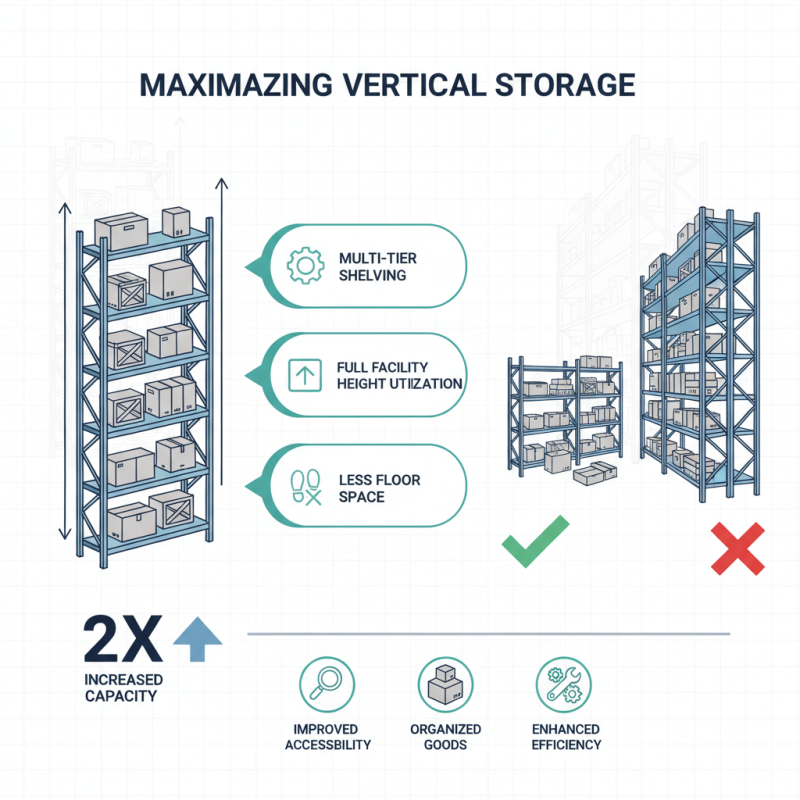

Designing efficient storage solutions in industrial settings involves several key principles that can significantly enhance operational efficiency. One of the foremost principles is to implement a strategic layout that maximizes space utilization. According to a report by the Material Handling Industry of America, facilities can achieve up to a 30% increase in storage capacity by utilizing vertical space effectively. Racking systems that extend upwards can reduce the footprint required for storage, allowing for the accommodation of more products without the need for additional floor space.

Another critical principle is to employ advanced inventory management techniques. Technologies such as Automated Storage and Retrieval Systems (AS/RS) can streamline the process of stock management. A study from the Warehouse Education and Research Council indicates that companies using AS/RS report a 20% reduction in labor costs and a 15% increase in order accuracy. By implementing systems that facilitate real-time data tracking and management, businesses can reduce overstocking and understocking scenarios, ultimately leading to more efficient storage practices.

Finally, proper training and safety measures must be incorporated into the design of storage solutions. A recent safety report from the National Institute for Occupational Safety and Health highlighted that more than 20% of workplace injuries occur in storage areas due to improper handling and organizational practices. Establishing clear protocols and providing regular training can mitigate risks and ensure that storage facilities operate efficiently and safely, enhancing overall worker productivity and morale.

Techniques for Maximizing Vertical Space in Storage Areas

Maximizing vertical space in storage areas is essential for enhancing efficiency in industrial storage solutions. One effective technique involves the implementation of multi-tier shelving systems, which utilize the full height of the facility to store goods. By designing rows of shelves that stack products upwards, organizations can significantly increase their storage capacity without the need for additional floor space. This approach not only helps in decluttering the ground area but also improves accessibility to items by organizing them according to size and frequency of use.

Another strategy is the use of adjustable racking systems, which allow businesses to customize shelf heights based on the type and size of inventory. This flexibility ensures optimal use of vertical space by accommodating varying product dimensions, thus preventing wasted storage potential. Additionally, incorporating vertical lifts and automated retrieval systems can further elevate storage efficiency by facilitating quicker inventory access and organization. Properly training staff on efficiently utilizing vertical space, including safe handling practices when retrieving items from higher levels, is equally crucial to ensure an effective implementation of these storage techniques.

Implementing Inventory Management Systems for Better Efficiency

Implementing an efficient inventory management system is crucial for optimizing industrial storage solutions. According to the 2021 Inventory Optimization Report by the Institute of Supply Chain Management, companies that utilize robust inventory management systems see a 20-30% reduction in holding costs. This is achieved by strategically balancing stock levels, minimizing excess inventory, and preventing stockouts. The integration of automated inventory tracking tools can further streamline operations, as such systems provide real-time visibility into stock movements, allowing for timely decision-making.

Tips for enhancing your inventory management include adopting just-in-time (JIT) practices that align your inventory levels closely with production schedules. This reduces excess stock and storage requirements. Additionally, implementing advanced forecasting techniques, such as demand sensing and predictive analytics, can significantly improve inventory turnover rates, as highlighted by a recent report from Gartner, which found that businesses employing predictive analytics experience up to a 15% increase in overall inventory accuracy.

Moreover, evaluating your current storage layout and employing techniques such as ABC analysis can help prioritize inventory management efforts. This method categorizes inventory based on importance and turnover rates, enabling companies to focus on high-impact areas first. According to a study by the Warehousing Education and Research Council, organizations that adopt effective categorization strategies can improve picking efficiency by more than 50%. By leveraging these strategies, businesses can achieve maximum efficiency in their industrial storage solutions.

How to Optimize Industrial Storage Solutions for Maximum Efficiency

| Storage Type | Capacity (Units) | Utilization Rate (%) | Inventory Turnover (Times) | Management System Efficiency (%) |

|---|---|---|---|---|

| Pallet Racking | 1000 | 85 | 6 | 90 |

| Vertical Lift Module | 500 | 75 | 8 | 95 |

| Shelf Storage | 2000 | 80 | 5 | 87 |

| Mobile Shelving | 1500 | 90 | 7 | 93 |

Regular Maintenance and Evaluation of Storage Systems

Regular maintenance and evaluation of storage systems are crucial for maximizing efficiency in industrial operations. According to a report by the Warehousing Education and Research Council, companies that prioritize regular evaluations of their storage facilities can see productivity improvements of up to 20%. This is largely due to the identification of inefficiencies and areas for optimization that can be easily overlooked. By systematically assessing storage layouts and inventory management processes, businesses can streamline operations, reduce retrieval times, and minimize unnecessary costs.

To effectively maintain and evaluate storage systems, it’s essential to implement a regular schedule for inspections and updates. This includes checking shelving and racking systems for wear and tear, optimizing space usage, and ensuring that all inventory is accurately tracked. One helpful tip is to use barcode or RFID technology to monitor stock levels in real-time, which can significantly reduce errors and improve stock accuracy. Furthermore, engaging staff in these evaluations not only fosters a culture of continuous improvement but also leverages their firsthand knowledge of daily operations.

Another tip for enhancing storage efficiency is to analyze data from these evaluations routinely. Utilizing performance metrics such as picking accuracy, order fulfillment times, and space utilization rates can provide insights into areas where improvements can be made. Industry studies have shown that companies actively analyzing their storage metrics can increase overall operational efficiency by as much as 15%. By making data-driven decisions, businesses can adapt their storage solutions to meet evolving demands while maintaining high productivity levels.

Related Posts

-

How to Choose the Best Industrial Storage Solutions for Your Business Needs

-

Top 10 Industrial Storage Solutions to Optimize Your Warehouse Space

-

Top 5 Benefits of Using Warehouse Pallet Racks for Maximum Storage Efficiency

-

Top 10 Warehouse Racking Systems to Maximize Space and Efficiency

-

How to Choose the Right Warehouse Pallet Racks for Your Business Needs

-

Why Heavy Duty Racking is Essential for Efficient Warehouse Storage Solutions