Blog

Ultimate Tips for Choosing Warehouse Racking Systems?

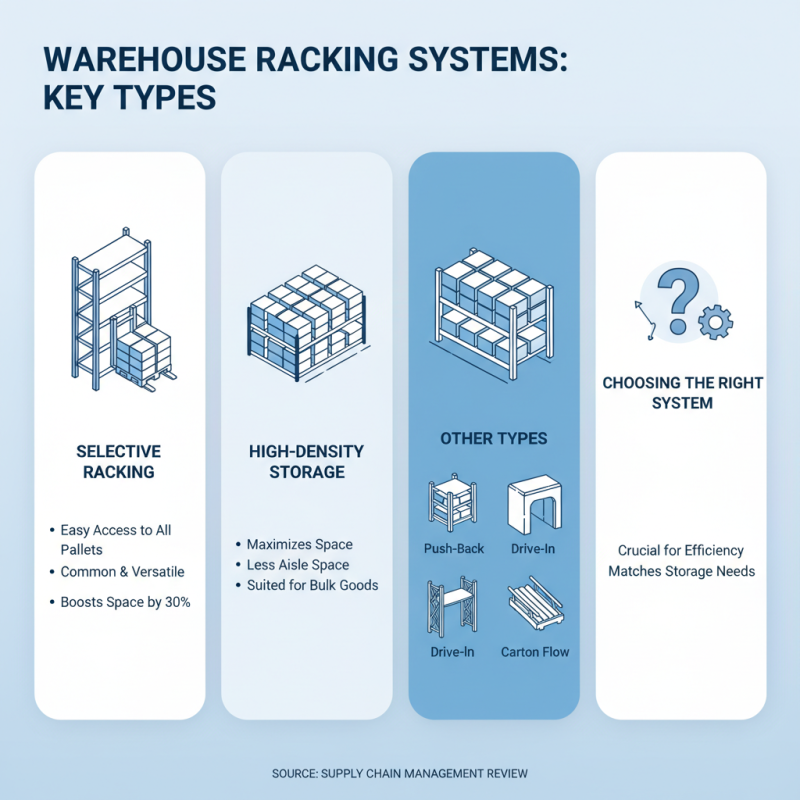

Choosing the right warehouse racking system is crucial for efficiency. A well-organized warehouse can significantly improve operations. Warehouse racking plays a vital role in maximizing space and ensuring easy access to inventory.

Different types of racking systems suit various needs. Consider your space's dimensions and the type of goods you store. Heavy items may require robust solutions, while lightweight products can use simpler setups. Understanding your inventory will prevent costly mistakes.

Not all racking systems are equal. Some might look appealing but may not meet safety standards. Evaluate the durability and stability of your chosen system. Regularly reassessing your racking setup is essential. It may not be perfect, but with careful consideration, you can optimize your warehouse for success.

Understanding Different Types of Warehouse Racking Systems

When selecting warehouse racking systems, understanding the different types available is crucial. There are various systems designed for specific storage needs. Selective racking is one of the most common types, allowing easy access to all pallets. According to Supply Chain Management Review, this system can increase storage space by 30%. However, it may not be the most efficient for high-density storage.

Another option is drive-in racking. This system is ideal for products with similar characteristics. It maximizes space but can lead to challenges with inventory rotation. A report from Modern Materials Handling indicates that while this system optimizes storage, it might complicate accessing older stock. This trade-off often requires careful consideration.

Lastly, pallet flow racking utilizes gravity to move goods. It's efficient for high-volume operations, but it is not cheap. Initial setup costs can be high. A 2022 report by the Warehousing Education and Research Council states that businesses must evaluate the long-term benefits versus the upfront investment. Impulsively choosing a system without proper analysis can lead to inefficient operations.

Evaluating the Load Capacity and Dimensions of Racking Systems

When evaluating racking systems, load capacity is a key factor. Each system has a specified weight limit. It is crucial to understand these limits. Overloading can cause serious accidents. Always refer to manufacturer guidelines. Consider the materials being stored. Heavy items require robust racks. If the load is unevenly distributed, the risk increases.

Dimensions play an important role as well. Measure your warehouse space before selecting racking. Consider ceiling height, aisle width, and accessibility. Racks that are too tall may lead to difficulties in retrieval. Narrow aisles save space but may limit movement. Striking a balance is essential. Think about the future, too. Will your inventory change?

Flexibility in design can help accommodate future needs. Adjustable shelving systems might be beneficial. They offer versatility as your requirements evolve. However, a more complex design may complicate assembly and use. Weighing these pros and cons is critical. Always reflect on how your choices impact efficiency. Your racking system should support your operations seamlessly.

Assessing Warehouse Space and Layout for Optimal Racking

When assessing warehouse space and layout, understanding dimensions is key. Measure ceiling height, floor space, and aisles carefully. Insufficient aisle space can hinder movement and efficiency. Calculate how much inventory you need to store. This helps determine the type of racking system.

Consider warehouse flow. Design a layout that allows easy access to fast-moving items. Avoid dead corners where inventory can pile up. If your layout is too cramped, it might lead to accidents or damage. Visualizing the flow can highlight potential issues before they become costly.

Flexibility matters in racking systems. As inventory changes, your needs may shift. Can your system adapt? Platforms or mobile racks offer options. Regularly evaluate your layout. Over time, what worked may not be ideal. Ensuring your warehouse evolves with your business is crucial.

Considering Safety Standards and Compliance in Racking Selection

When selecting warehouse racking systems, safety standards must be a priority. Different racking types have unique safety requirements. For instance, selective racking needs to comply with load distribution guidelines to prevent tipping. Regular inspection and maintenance are essential but often overlooked. Many warehouse managers neglect this, which can lead to accidents.

It's crucial to be aware of local compliance regulations. These can vary significantly from one place to another. Ignoring them can result in fines or worse, injuries. Training employees on proper loading techniques can also improve safety. Yet, many warehouses skip this step, hoping that employees will figure it out.

Consider the impact of your racking decision on overall workflow. Cluttered aisles can create hazards. Racks should allow easy access and visibility. Sometimes, this means sacrificing storage space for safety. It's not always easy to balance efficiency with compliance, but taking the time to reflect on safety will pay off in the long run.

Budgeting and Cost Analysis for Warehouse Racking Solutions

When budgeting for warehouse racking systems, it's crucial to consider various factors. Start by assessing your storage needs. Think about the types of products you'll store. This directly influences the racking style you choose. For instance, heavy goods might require more robust systems. Lightweight items can work with simpler designs.

Next, calculate the total cost of ownership. It's more than just the purchase price. Installation costs can add up. Don’t forget to factor in maintenance expenses. If a racking system requires frequent repairs, that adds to the budget over time. Failing to account for these hidden costs could lead to financial strain later.

Additionally, seek to maximize your space efficiently. A well-planned layout can mean fewer racks are needed. Yet, an inefficient structure can waste both space and money. Consider flexible solutions that can adapt to changing needs. Sticking with rigid designs might be limiting. Lastly, consulting with industry experts can provide invaluable insights. Real-time feedback can identify potential pitfalls in your plans. Rethinking your strategy is essential for long-term success.

Related Posts

-

2026 Top Trends in Pallet Racking Innovations and Solutions?

-

2026 Best Racking System Solutions for Efficient Storage Management?

-

2025 Guide: How to Efficiently Rack Shelves for Maximum Space Utilization

-

10 Best Racking and Shelving Solutions for Efficient Storage Management

-

Top 10 Racking System Solutions for Optimal Warehouse Efficiency

-

Top 5 Best Cantilever Racking Systems for Maximizing Storage Efficiency