Blog

2025 Top Cantilever Racking Solutions for Efficient Warehouse Storage

In the evolving landscape of warehouse storage solutions, cantilever racking has emerged as a pivotal system for optimizing space and enhancing operational efficiency. According to a report by the Warehouse Management Association, approximately 60% of warehouses are expected to incorporate cantilever racking systems by 2025, driven by the growing demand for storing long and irregularly shaped goods. As inventory management becomes increasingly complex, leveraging a flexible storage system like cantilever racking not only maximizes vertical space but also simplifies access to materials, thereby boosting productivity.

Renowned industry expert, Dr. Morgan Shaw, a leading consultant in warehouse logistics, emphasizes the significance of this storage solution: "Cantilever racking is not just about storage; it's about creating a streamlined workflow that eliminates bottlenecks and improves inventory turnover." With advancements in design and materials, modern cantilever racking solutions are tailored to accommodate a diverse range of items, making them vital for sectors such as manufacturing, distribution, and retail. As we approach 2025, the integration of these innovative racking systems will undoubtedly play a crucial role in shaping the future of efficient warehouse operations.

Overview of Cantilever Racking Systems and Their Benefits

Cantilever racking systems are increasingly becoming a vital component of modern warehouse storage solutions. These innovative systems are designed to handle long, bulky items that traditional shelving cannot accommodate effectively. With their open design, cantilever racks allow for straightforward loading and unloading, making them ideal for storing items such as lumber, pipes, and furniture. The flexibility of cantilever racks further enhances their utility, as they can be easily adjusted to suit varying item sizes, allowing warehouses to maximize vertical space and improve overall efficiency.

One significant benefit of cantilever racking is its ability to increase operational efficiency. By providing easy access to stored goods, warehouses can reduce pick times and streamline inventory management processes. Additionally, cantilever racks typically require less aisle space than conventional systems, enabling tighter storage configurations and more effective use of warehouse floor space. This not only aids in maximizing storage capacity but also facilitates better organization and minimizes the risk of damage to the goods stored, ultimately supporting a more productive and safe work environment.

Key Features to Consider When Choosing Cantilever Racking Solutions

When choosing cantilever racking solutions for your warehouse, there are several key features to consider that can significantly enhance storage efficiency. First and foremost, evaluate the load capacity of the racking system. It is vital to select a system that can safely support your heaviest items without compromising structural integrity. Consider the material construction of the racks; steel options tend to offer superior strength and durability, ensuring that your investment withstands daily operations.

Another important feature is the adjustability of the racking system. Look for solutions that allow for flexible shelf heights and configurations to accommodate various product sizes. This adaptability can help maximize vertical space, which is often underutilized in warehouses. Additionally, a well-designed cantilever rack should provide easy access to items, minimizing retrieval times and improving workflow efficiency in your storage area.

**Tips:** Regularly assess the condition of your cantilever racks to identify any potential wear and tear, especially if you store heavy or bulky items. Ensure that the racks are installed on a solid, level surface to prevent tipping and enhance stability. Lastly, consider implementing a systematic labeling or inventory management system in conjunction with your cantilever racks to streamline operations and facilitate quicker access to materials.

Top 2025 Innovations in Cantilever Racking Technology

The landscape of warehouse storage is undergoing a significant transformation, particularly with advancements in cantilever racking technology. As businesses increasingly prioritize efficiency and organization, 2025 is poised to witness innovative solutions designed to maximize space usability and streamline operations. Reports indicate that the global market for cantilever racking is expected to grow at a CAGR of 5.2% by 2026, driven by the rising demand for optimized storage solutions in various industries, including retail and manufacturing.

Among the key innovations shaping the future of cantilever racking are smart storage systems that integrate IoT technology. These systems can monitor inventory levels in real-time, providing data that helps warehouse managers make informed decisions about restocking and space allocation. Another notable trend is the development of adjustable cantilever racking, which allows easy customization to accommodate various lengths and weights of items, enhancing flexibility in warehouse operations. According to industry analytics, companies that adopt these advanced racking systems can improve their operational efficiency by up to 30%, reducing labor costs while increasing throughput.

Moreover, sustainability is becoming a critical factor in the evolution of cantilever racking solutions. New materials and designs are being developed to enhance the durability of racks while reducing their environmental impact. Energy-efficient lighting and modular components are increasingly being incorporated, contributing to more sustainable warehouse practices. As organizations seek to improve their overall environmental footprint, these innovations not only promote operational efficiency but also align with corporate sustainability objectives.

2025 Top Cantilever Racking Solutions for Efficient Warehouse Storage

This chart illustrates the key metrics of the top cantilever racking solutions for 2025, highlighting innovations in load capacity, space utilization, installation time, and cost.

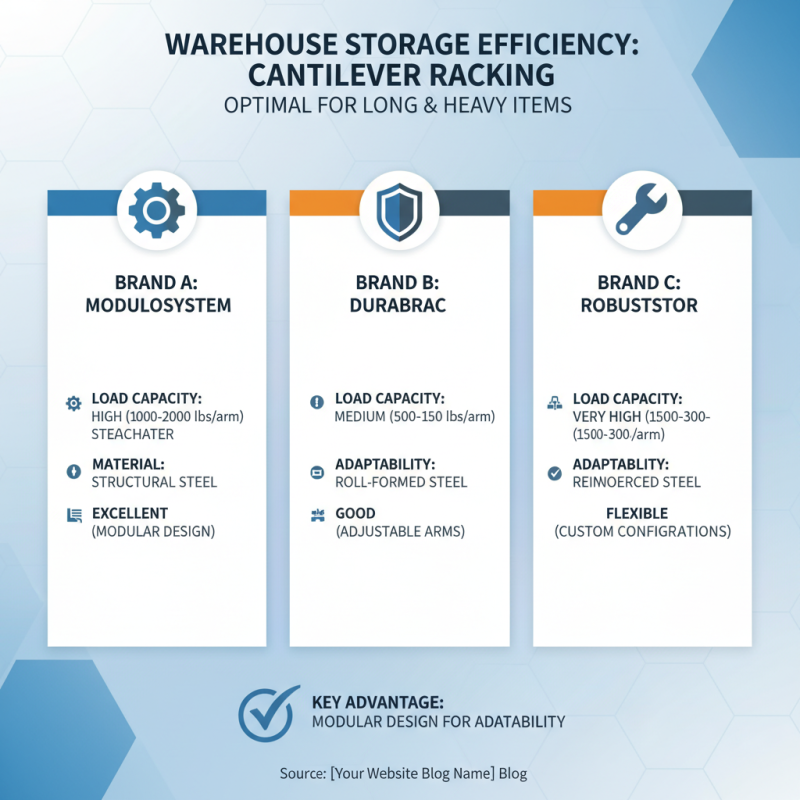

Comparative Analysis of Popular Cantilever Racking Brands

When evaluating the efficiency of warehouse storage, cantilever racking systems emerge as a leading choice for businesses, particularly for handling long and heavy items. The comparative analysis of popular cantilever racking solutions reveals key features that distinguish one brand from another, focusing on aspects such as load capacity, material longevity, and adaptability in various storage environments. A standout trait among successful racking systems lies in their modular design, allowing warehouses to adjust configurations as inventory needs change.

Moreover, safety features play a crucial role in the selection process. Effective cantilever racking systems incorporate innovative design elements that ensure stability under heavy loads while minimizing the risk of tipping or collapse during operations. Additionally, the ease of installation and maintenance is paramount, as warehouses seek solutions that not only optimize their space but also reduce downtime. Thus, a thorough analysis of these factors—ranging from structural resilience to operational efficiency—equips warehouse managers with the insights needed to make informed decisions tailored to their specific storage demands.

Best Practices for Implementing Cantilever Racking in Warehouses

Implementing cantilever racking in warehouses offers significant advantages for handling bulky and irregular items. One key best practice is to conduct a thorough inventory assessment prior to installation. Understanding the dimensions, weight, and handling requirements of the stored materials is critical for designing a racking system that maximizes available space and enhances operational efficiency. Additionally, engaging staff in the layout design process ensures that the racking configuration aligns with daily workflows, minimizing disruptions and optimizing movement.

Another essential practice is to prioritize safety during the installation and usage of cantilever racking. This includes training personnel on proper loading techniques and weight distribution to prevent accidents or collapses. Regular maintenance checks should also be instituted to ensure that the racking system remains stable and secure over time. Marking load limits clearly on each arm and implementing clear signage throughout the storage area can further enhance safety measures, creating a more productive and secure working environment. By adhering to these best practices, warehouses can realize the full potential of cantilever racking systems, leading to improved organization and efficiency.

2025 Top Cantilever Racking Solutions for Efficient Warehouse Storage

| Dimension | Value | Recommended Usage | Benefits |

|---|---|---|---|

| Arm Length | 48 inches | Heavy-duty storage | Increased load capacity |

| Rack Height | 120 inches | Bulk storage | Maximized vertical space |

| Load Capacity | 3,000 lbs/arm | Long items | Efficient space usage |

| Material | Steel | Outdoor & indoor storage | Durability and strength |

| Customization | Yes | Specific inventory needs | Tailored solutions |

Related Posts

-

What is Cantilever Racking and How Does It Benefit Your Warehouse Storage

-

Top 10 Industrial Storage Solutions to Optimize Your Warehouse Space

-

How to Choose the Right Warehouse Pallet Racks for Your Business Needs

-

Why Heavy Duty Racking is Essential for Efficient Warehouse Storage Solutions

-

Ultimate Guide to Choosing the Best Pallet Shelving for Your Warehouse in 2025

-

Top Heavy Duty Racking Systems for Efficient Warehouse Storage in 2025